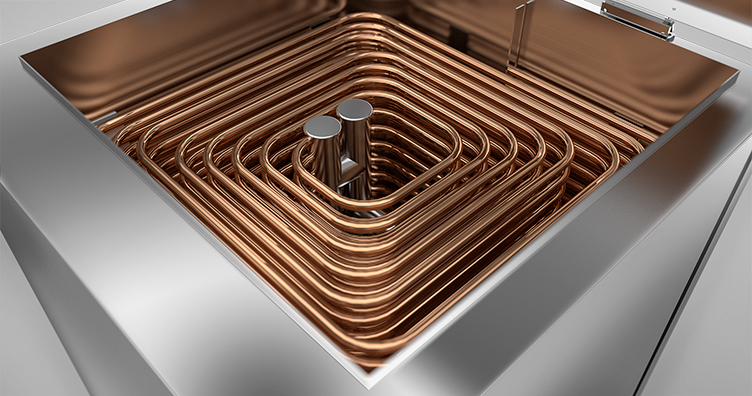

The cool water absorbs the heat from the hot substances, returning to the machine to be cooled again. Thus, succeeding in pasteurizing mixtures for ice cream, which need an abrupt temperature drop; as well as accomplishing many other processes in the food industry and other industries. (For example, in the mechanical industry, the water refrigeration unit is used to cool plastic parts immediately after they are injected into the moulding.)

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

Business purpose

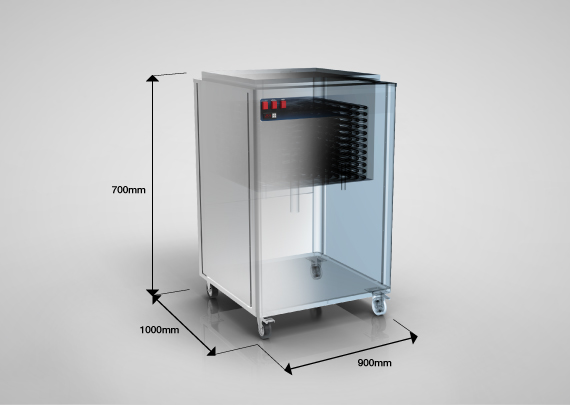

For medium to large sized producers of industrial ice cream, that use multi-plate heat exchangers in their processes.

Also, for other companies in other industries that need to use cold water in their processes.

Pasteurizing plants, from 250 liters/hour.

1. Uses the latest technology, with the lowest energy consumption in the market. Reduces costs due to the simplicity and efficiency of its design.

2. Higher cooling fluid savings: It uses only 50 liters / 13.21 gal, in comparison to the 100 liters / 26.42 gal tanks used by the traditional units, allowing it to quickly start operations, saving more energy.

3. A filtering system prevents the heat exchanger from clogging.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.