*Please check the laws in your country about food preparation before finish your purchase.

A semi-automated machine for producing water-based (gooseberry, pineapple, lemon, etc) or milk-based (chocolate, vanilla, etc) popsicles.

It is a practical and fast machine, endorsed by numerous successful businesses.

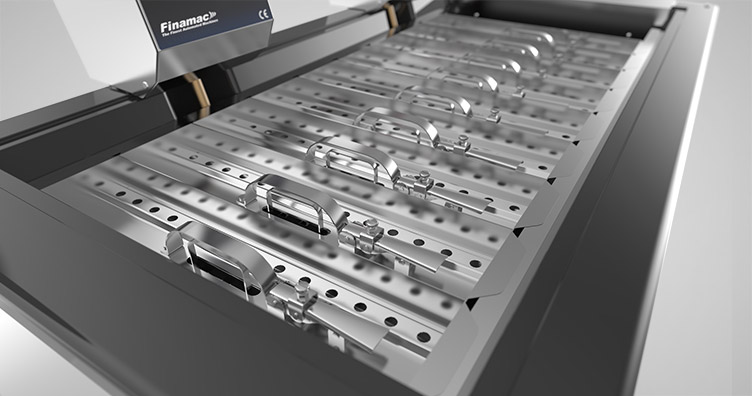

Produces 700/900 popsicles/hour, with 10 moulds of 28 cavities each.

*Production depends on the climatic conditions of the location where the machine is installed. Depending on the shape mold brand, the machine capacity can range from 9 or 10 28-cavity shape molds.

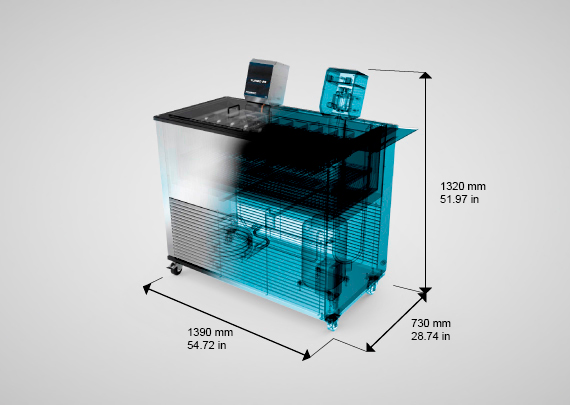

Compact, light, and durable. Rotary/lock wheels make it easy to move and transport.

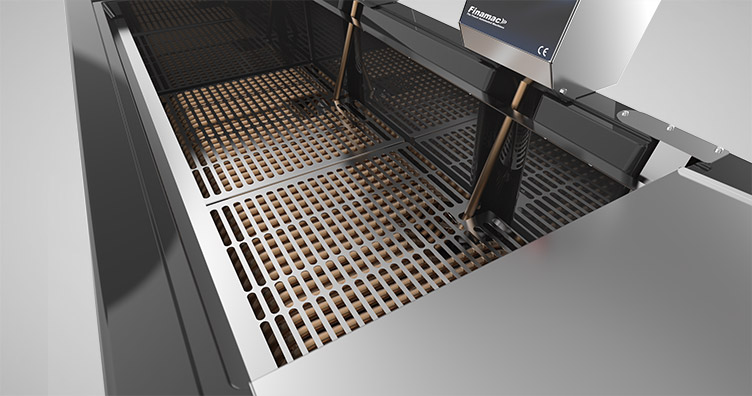

Unibody cabinet made from stainless steel.

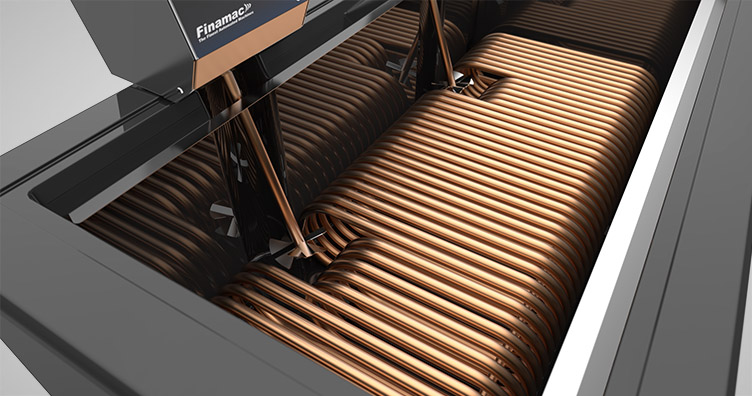

Powerful, practical, and silent: High-efficiency hermetic compressor. Low noise level. Low power consumption.

Three-phase 220V, 50/60 Hz; water condensed; tropicalized refrigeration.

Business purpose

For medium-sized producers who already have some experience in this industry, or professionals who want to increase their production in a modular way, having the ability to add one or more piece of equipment into the production line, according to demand.

To obtain the high-quality industrial standard ice cream, even in medium quantities, through controlled production cycles.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

1 Turbo 25 + 1 Mixer 15. Production of up to 900 popsicles per hour.

2 side-by-side Turbo 25 machines. Connected at the same time, they are able to produce up to 1800 popsicles per hour. Only one machine an be connected during low sales period (i.e. cold weather or rainy days).

Can produce ice using special moulds.

Ultra fast cooling of drinks, juices etc.

Abrupt cooling of ice cream mixtures, heated by flame, to complete the pasteurization cycle.

1. A top-of-the-line machine that has a track record of successful results among experienced leaders in the popsicle industry.

2. The best investment/return rate in the food production industry.

3. Easy to operate, install, and transport.

4. Occupies 40% less space than that of conventional equipment.

5. The best production/time rate among equivalent equipment.

6. The latest technology in popsicles production.

7. Durable and with a high resale value. Considered to be “cash money” in the market.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.