It is an indispensable accessory that removes the heat generated by machines used to make ice-cream and popsicles.

The freezing process of ice-cream and popsicles is very similar to the operation of an air-conditioner. Ice-cream/popsicle machines generate heat which needs to be blown out of the room similar to the heat that is blown out of the room by an air-conditioner.

It is an exchange of heat where air-conditioning steals heat from the room and cools it, then throws the unwanted heat out. The ice-cream/popsicle machine steals heat from the product (popsicles or ice-cream) and needs to then also throw this heat out of the room. If this heat is not thrown out into the environment the machines will overheat, causing lost of efficiency or stop working.

There are several ways to remove heat from the room. The first is through a “radiator” (known as the air condenser) which consists of aluminum fins that must be directed outwards. In air-conditioners the radiators that generate the heat are placed outside the home or office. In ice-cream/popsicle machines the radiator is placed at the bottom of the cabinet itself, hence the need to leave these machines facing a door or window vent.

The second way to remove this heat from the enclosure is to use a water circulation system that passes through the ice-cream/popsicle machine and is pumped into a water cooling tower. This tower is located outside the grounds, usually in high places and well ventilated.

This system has a huge advantage over the “air cooler” because water can be maintained at a temperature lower that the temperature of air, which gives a more powerful heat exchange. Besides being a silent system it is also completely clean.

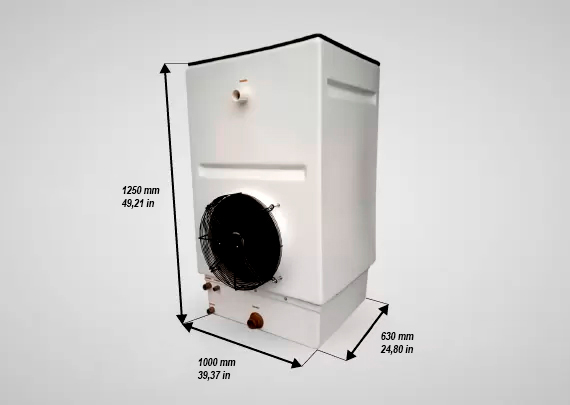

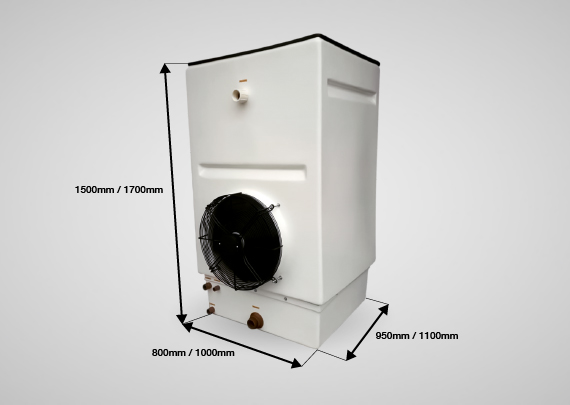

This is where the water cooling tower comes in handy. It is simply nothing more than a spray of hot water with a flow of air in a reverse flow chiller. The hot water coming from the ice-cream/popsicle machine is sprayed and cooled by a powerful fan, returning the machine to the required cold temperature.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

1. All ice-cream or popsicle machines (PRO 16 line, Super C line, Turbo 25 line and onwards) with capacity exceeding 200 popsicles/hour or 60 liters of ice-cream/hour.

2. A single tower can serve more than one piece of equipment simultaneously or separately.

3. On cold days it can work with less intensity and save energy.

4. Showcases exhibiting ice-cream (Elegance and Supreme) can also use the cooling tower. The external tower avoids heat and noise created from fans within the machine.

5. Pasteurizers of mixtures for ice-cream and popsicles above 60 liters (PP 110 onwards) also require cooling towers.

6. Conjugate machine as PP12 (pasteurization + ice-cream production) also utilizes cooling towers.

1. Provides maximum performance to your ice-cream/popsicle machines, even on the hottest days.

2. Prolongs life of equipment by maintaining good working condition within controlled temperatures.

3. Provides a silent working environment due to ventilation being outside of enclosure.

4. Allows for installation of multiple devices on the same tower, depending on their ability.

5. Saves water because it is recirculated and cooled. It would require a large volume of water to create the same effect.

6. Its low cost is a huge benefit when it comes to the production of ice-cream and popsicles.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.