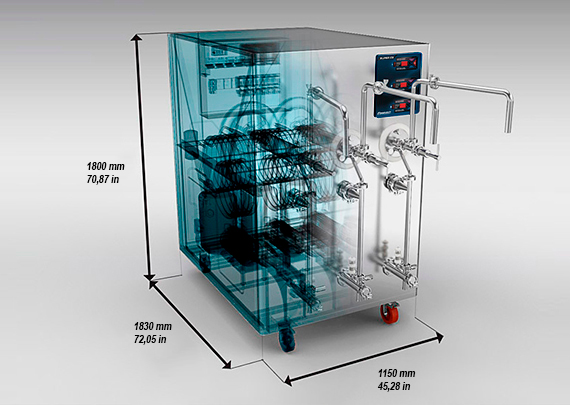

Three "Super C" model machines are mounted in the same cabinet to reduce space and cost. These three machines can operate at the same time, simultaneously producing the same flavor, or separately, to produce three distinct flavors.

It is most commonly used to produce three distinct flavors at the same time.

It produces 450 to 600 liters (118.88 to 158.50 gal) of ice cream/hour, with 100% over run, at a final temperature of -5°C / 23° F.

*Production depends on the climatic conditions of the location where the machine is installed.

All operations are commanded electronically - pump speed, motor amperage indication, and cylinder pressure. Using a frequency inverter to control the pump speed makes the operation less strenuous which increases its longevity.

A defrost gas injection decreases production to 3 x 100 l (26.42 gal)/h.

Air incorporation can be adjusted between 50 and 120%.

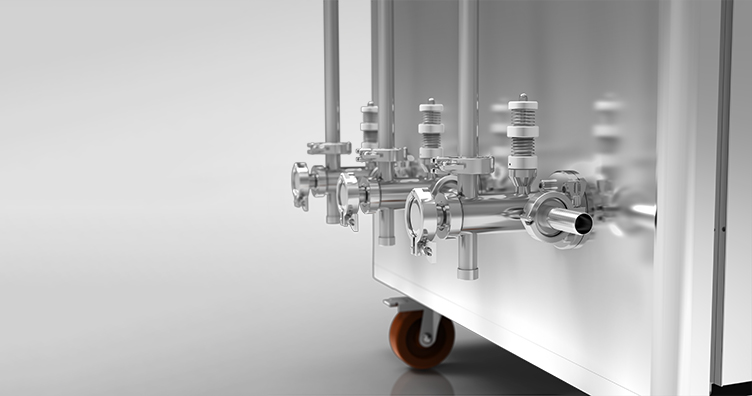

An inlet and outlet on the front of the machine makes it easy to handle and clean.

A working pressure of up to 11 bars allows connection to machines for ice cream extrusion and confectioning.

Uses tropicalized refrigeration and ecologic gas.

Compact and easy to disassemble and transport.

Business purpose

For experienced ice cream makers who need to produce three distinct ice cream flavors at the same time, or produce only one flavor using all three cylinders simultaneously or separately - depending on demand.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

1 Super C3 + 1 complete pasteurization plant.

1 Super C3 + 3 PP110.

1 Super C3 + 1 Gyro Filler.

1. Produces three different flavors at the same time; up to 200 liters/hour per flavor.

2. Substantially increases profits by incorporating up to 120% more air in the ice cream (overrun of 120%) and 30% in acai production.

3. Substantially increases the quality of the ice cream, since the high-pressured aeration and beating improves the texture, taste, and stability of the final product.

4. Economizes ingredients, like stabilizers and flavorings, because the whole process is done under high pressure, which makes it easier to mix and produce ice cream. Conventional machines, that don’t use a pressure pump, must use larger quantities of ingredients to produce the same effect.

5. It is the only machine that uses a cylinder where the ice cream is beaten - the same technology used by the Aerospace Industry. It is a thin cylindrical wall of extremely compacted material that substantially increases the freezing capacity. This special high precision cylinder is only available from Finamac.

6. Easy to operate, install, and transport.

7. Produces high quality industrial standard ice cream; not only more hygienic, but also with better texture, taste, color, aeration, time of conservation, melting resistance, and other characteristics easily noticed by discriminating consumers.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.