*This machine is not certified by ETL/UL/NSF rules.

*Please check the laws in your country about food preparation before finish your purchase.

PROCESS

Prepares and heats all ingredients up to 80°C / 176°F in the process tank (preparation and heating time: 50 min.).

Activates the pump in order to transfer the mixture into the transfer tank.

Begins preparing a new mixture in the process tank.

Connects the cooling tower and the cooling water reservoir.

Activates the circulating pump to force the mixture through the homogenizer.

When leaving the homogenizer, the mixture circulates through the heat exchanger, dropping the temperature from 80°C to 4°C / 176°F to 39.2°F, then conducts the pasteurized mixture to a maturation vat (refrigeration time to 4°C / 39.2°F: 60 min).

After the cooling is concluded, the process restarts by loading the new mixture, which has already been prepared in the process tank, into the transfer tank (this cycle is continuosly repeated).

The maturation vat is connected to a continuous freezer through a non-toxic hose.

The continuous freezer (SUPER C, SUPER C PLUS, SUPER C3 or C-JET) has a special pump that suctions the mixture from the maturation vat and produces the ice cream. Finamac™ continuous freezers allow enough outlet ice cream pressure to supply automatic filling machines to fill cups, sundaes, cones, etc.

Has the optional capability to connect the continuous freezer to a Finamac™ Fruit Feeder to introduce pulps and solid ingredients into the ice cream.

*Production depends on the climatic conditions of the location where the machine is installed.

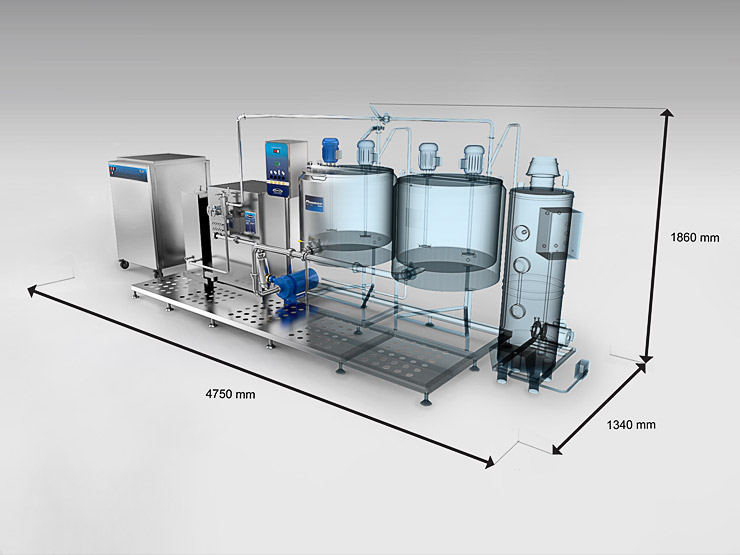

COMPONENTS DESCRIPTION

- HEATER

PURPOSE: To heat the thermal transfer fluid (water) which will circulate in the processing tanks, transferring heat to the mixture through thermal conduction.

DESCRIPTION:

Effective thermal power: 18000 Kcal/h.

GLP (heating gas) consumption: 1.56 kg (3.44 lb)/h.

Thermal insulation: involved with glass wool blanket (elevated insulation index).

Burner maximum pressure: 280 mm c.a.

External shell: AISI 304 stainless steel.

Burner: designed to burn GLP or natural gas, as required.

Temperature control: Automatic, through a solenoid valve and adjustable electronic thermostat.

Safety: Has an emergency valve, that immediately cuts off the passage of gas, in case the pilot light goes out.

Electric panel: made of steel with electrostatic paint, IP55.

Power: 0.3 KW, 220V, monophase.

- THERMAL FLUID PUMP

PURPOSE: Circulates the thermal transfer fluid, originating from the heater and then moves around the processing tanks.

DESCRIPTION:

Motor protected with AISI 304 stainless steel.

Refrigerated mechanical seal, specific for hot liquids and sanitary conception.

Dismountable frames, fixed by fast closing clamps, for easy cleaning.

Allows CIP washing.

Motor: 220/380V, Tri-phase, ½ hp, 60 Hz (50 Hz), IP55.

- PROCESSING TANK

PURPOSE: The tank where ice cream ingredients are mixed and heated. Capacity: 300 liters / 79.25 gal.

DESCRIPTION:

AISI 304 stainless steel, inner tank with rounded edges and polished sanitary finishing, made for easier cleaning.

Tilted-lid, to facilitate inner tank access.

The circulation of the thermal transfer fluid begins at the bottom and moves around the tank using an alveolar system (replacing the old systems of copper tubing rolled around the tank, half-pipe system or involved), allows a higher rate of heat transfer and offers more energy savings.

Two blenders with intense revolution capability, provide a wide vortex for mixing the product.

Helix with a wide cutting surface.

Insulation between the inner and outer tanks made of injected polyurethane foam.

Digital thermometer for the heating temperature confirmation.

IP54 electric motors.

Power: 2.2 KW, 220V, tri-phase.

- TRANSFER TANK

PURPOSE: The tank where the ice cream mixture is stored after passing trough the multi-plate heat exchanger. Capacity: 300 liters / 79.25 gal.

DESCRIPTION:

AISI 304 stainless steel, inner tank with rounded edges and polished sanitary finishing, for easier cleaning.

Tilted-lid, to facilitate inner tank access.

Low rotation blender.

Insulation between the inner and outer tanks made of injected polyurethane foam.

Power: 60 Watts, 220V, tri-phase.

- TRANSFER PUMPS

PURPOSE: To transfer the heated mixture between the tanks and up to the homogenizer, or multi-plate heat exchanger.

DESCRIPTION:

Motor: 220V, tri-phase, ¾ hp, 60 Hz, IP 55.

Motor protected with AISI304 stainless steel.

Refrigerated mechanic seal, specific for hot liquids and sanitary conception.

Dismountable frames, fixed by fast closing clamps, for easy cleaning.

Allows CIP washing.

- LINE FILTER

PURPOSE: To retain impurities and particles not dissolved in the mixer tank.

Constructive material: AISI 304 stainless steel.

Dismountable.

Connects to the process with tri-clamp connections.

- HEAT EXCHANGER

PURPOSE: To cool the homogenized mixture, completing the pasteurization cycle.

This cooling occurs by turbulent flowing through the lines formed between the plates, in thin threads that are a millimeter thick. On one side of the plates the product circulates to be cooled; on the other side, counterclockwise, the cooling fluid flows in two stages: First, it cools the mixture from 80ºC to 32ºC (176ºF to 89.6ºF) with water derived from the hydraulic circuit of the cooling tower; second, it cools down from 40°C to 4°C (104°F to 39.2°F) with a 30% water and alcohol solution. Outlet temperature of mixture: + 4ºC / 39.2°F. Solution temperature derived from the cooling unit: + 2°C / 35.6°F.

DESCRIPTION:

Counter-flow heat exchanger uses AISI 316 stainless steel plates, insulated with dismountable nitrile rubber joints.

Capacity: 300/600/1200 liters (79.25/158.5/317 gal)/h (mix with 38% solids).

Double passage circuit:

First Stage: Cools the incoming mixture at 80°C to 32°C / 176°F to 89.6°F, due to thermal exchange with 1800 L (475.51 gal)/h of water from the cooling tower, incoming at 28.0°C (82.4°F) and out at 35.1°C (95.18°F), pressure drops on the mixture side of 5.0 mCA, and on the tower water side at 0.5 mCA. Amount of heat exchanged: 12672 kcal/h.

Second Stage: Cools the incoming mixture from 32.0°C (89.6°F) to 4.0°C (39.2°F), due to thermal exchange with 1500 L (396.26 gal)/h of cooled water/alcohol solution, incoming at 2.0°C (35.6°F) and out at 7.0°C (44.6°F), pressure drops on the mixture side of 7.5 mCA, and on the cooled water side at 0.5 mCA. Amount of heat exchanged: 7392 kcal/h.

- WATER COOLING UNIT

PURPOSE: To supply cooled water between 1.0°C (33.8°F) and 6°C (42.8°F) to the second stage of the multi-plate heat exchanger.

Automated operation with low consumption and noise, including:

Protection against short circuit and overloads;

Powerful hermetic compressor;

Multi-plate evaporator, made of 316 stainless steel and copper. Connections in stainless steel. Welded material 99.9% copper;

Tube-in-tube condenser (parts in contact with water made of copper);

Thermostat for the temperature control;

High pressure condensation pressostat;

Nominal capacity: 12,500 Kcal/h;

Cooled water flow: 7.50 m3/h at 25 m.c.a.;

Cooled water temperature: adjustable from 1.0°C (33.8°F) to 25°C (77°F);

Condensation: water, minimum flow of 3.0 m3/h at 28ºC;

Electric power: 220V, tri-phase, 220V command, IP 54, 4.7 KW;

Connections: 1” (cooled water), ¾” (condensation water), ½” (replacement water).

- TRANSFER TUBING

The pasteurized mixture is transported to the maturation tank through a clear non-toxic plastic hose with 1” inner diameter.

Connection to the process: 1” diameter sanitary tri-clamp, working pressure of 6 bars.

- COMMAND PANEL

Made of carbon steel with electrostatic paint.

IP 55 protection grade.

Electric frame:

Built-in command panel with frontal door access. Electric contact switches, thermal relays of protection against current overload.

Electronic sensor temperature for the boiler and process tank.

Command frame:

Programmable microprocessed temperature controller with safety parameters configuration.

Light bulb indicator for components operation.

Light bulb indicator for components failure.

Boiler protective system with programmable maximum heating temperature (avoids burning the mixture with the excess temperature).

Water dispensing system, with automatic flow control, assures the uniformity of the recipe, avoiding operational errors, such as incorrect dosage. Optional: automated system through CLP.

- COOLING TOWER

DESCRIPTION: The horizontal-type water cooling towers push the air from the bottom to the top. They are designed to be compact and simple, reducing the overall size while achieving maximum capacity. Its system reduces the loss of water through evaporation and dragging, decreasing the need of completion.

CHARACTERISTICS:

a) Body constructed in PRFV (polyester reinforced with fiberglass) self-portable and non-corrosive.

b) Internal filling made of polypropylene, assembled in compact blocks of high mechanical resistance and easy washing/maintenance.

c) Spatter eliminator in polypropylene, which limits water flow circulation dragging loss by 0.15%.

d) Water distributed in PVC tubes reinforced with PRFV, with low pressure pulverizer nozzles.

e) Hermetic motor, IP 55 grade protection.

f) Axial-type helix directly coupled to the motor, aluminum cube and polypropylene blades with air-foil profile, electronically balanced.

- HOMOGENIZER (OPTIONAL)

Equipment designed to homogenize the mixture to the smallest particle size possible, yielding the highest quality final mixture with maximum air incorporation.

Operates with high pressure, in order to force the perfect mix between fats, solids, and liquids.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.