PP60 pasteurizer is the first machine in the world which doesn’t use electric resistance or burning gas for the heating process of the ice cream mixture.

A heat pump system is used instead of traditional components. Incredible, isn’t it?

Patented by Finamac™, PP 60 Pasteurizer works perfectly for small production quantities, eliminating many complicate systems usually present in conventional pasteurizers, beyond the significant operation cost and final price reductions.

The pasteurization process consists in heating the mix up to 65°C / 149°F, maintain this temperature during 30 minutes, and abrupt cooling to 4°C / 39.2°F, eliminating the noxious microorganisms found in the milk and other ingredients. Thermal shock from 75°C to 4°C / 167°F to 39.2°F

to 4°C / 39.2°F is possible as well.

Pasteurization not only guarantees a healthy ice cream but also increases the mixture capacity to be mixed with air and stabilizers, offering a softer and more stable ice cream.

*Equipment with air condensation have reduced production by 10% to 50%, from an ambient temperature above 28°C to 45°C / 82.4°F to 113°F.

*The production depends on climatic conditions and installation of the places where the machine is located.

Business purpose

For small ice cream and Popsicle makers who intend to obtain industrial quality, exempt from noxious bacteria. It is also important for those interested to distribute their products, since the pasteurization process strongly increases the product shelf life.

*This machine is not certified by ETL/UL/NSF rules.

*Please check the laws in your country about food preparation before finish your purchase.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

1 PP 60 + 1 up to 3 Pro4 batch freezer.

1 PP 60 + 1 up to 3 Turbo8 Popsicle machine.

1 PP 60 + 1 SuperC continuous ice cream freezer.

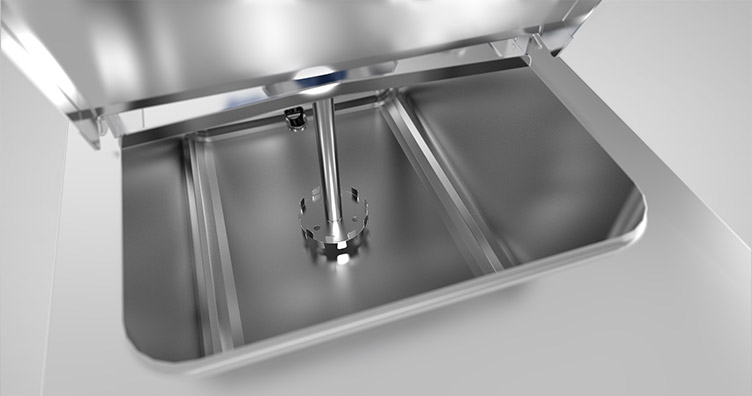

1. Pasteurizer and aging tank, in the same equipment.

2. Up to 75°C / 167°F heating.

3. Soft cooling (65°C / 149°F per 30 min to 4°C / 39.2°F) or abrupt cooling (75°C to 4°C / 167°F to 39.2°F) and automatic temperature stabilization at 4°C / 39.2°F during the aging process, with time set by the operator.

4. Final product cost reduction: Pasteurized and cooled mix represent significant cost reductions on ice cream freezer or Popsicle machine operation. Also, the new and revolutionary heating system practically doesn’t contribute in the product final cost, since it considerably saves energy consumption.

5. Easy to use: Automatic temperature control, no previous expertise needed.

6. High productivity: increases the mix over-run and guarantees the ice cream or Popsicle shelf life.

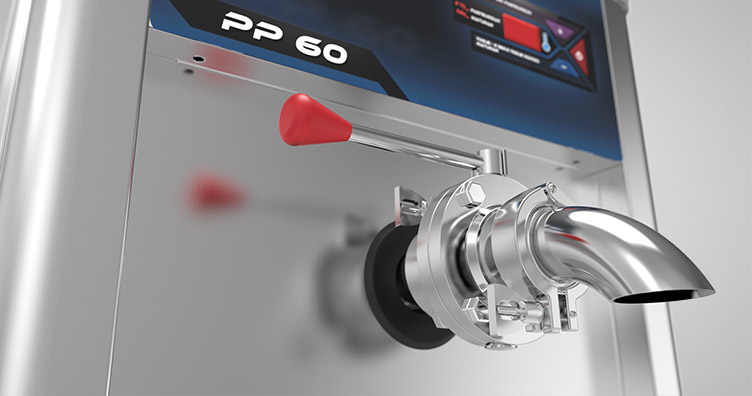

7. Easy to clean: Outlet valve 100% sanitary, no stationary mix inside during the pasteurization process. Rectangular tank, with rounded edges.

8. Product quality: Ice cream quality absolutely assured, not only under the hygiene aspect but also in terms of texture, aeration, flavor, color, durability, melting resistance and others, easily identifiable by demanding customers.

9. Considerable energy savings: the exclusive and revolutionary heating system reduces energy consumption and maintenance expenses, since few parts are used and no electrical resistances nor heating gas devices are present in this equipment.

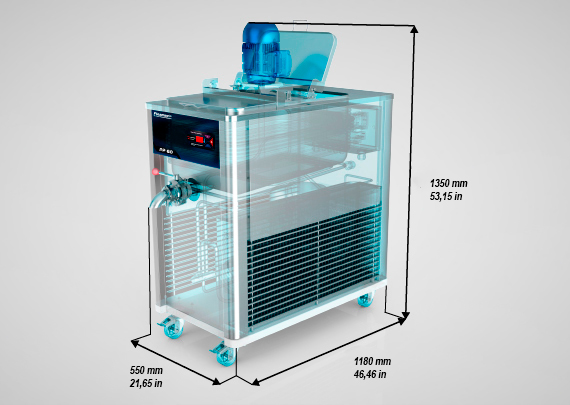

10. Easy to install: Air condensed (doesn’t require water to refrigerate the equipment) and mono phase electric connection.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.