*This machine is not certified by ETL/UL/NSF rules.

*Please check the laws in your country about food preparation before finish your purchase.

An automated machine used for pasteurizing ice cream and popsicles mixtures.

The pasteurization process involves heating the mixture up to 80º C / 176°F and then cooling it abruptly to 4º C / 39.2°F, in order to eliminate toxic micro-organisms that are found in milk and other ingredients.

Pasteurization not only ensures a healthy ice cream but also increases the mixture’s capacity to fuse with air and stabilizers, making the cream much softer and more durable.

Versatility: pasteurizing and maturation (aging) happens in a single tank.

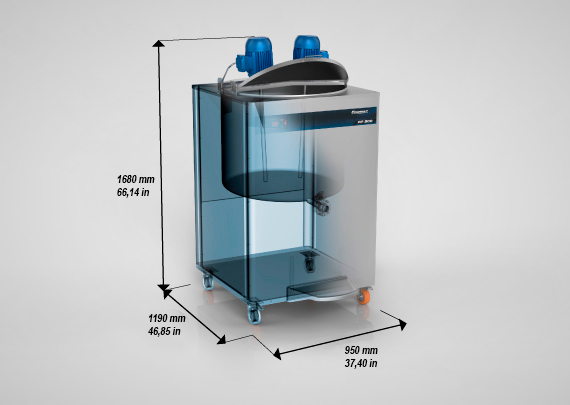

Profitable volume: 52.8 gallons / 200 liters.

LPG gas consumption: 1.12 Kg per 52.8 gallons (200 liters) of heating cycle.

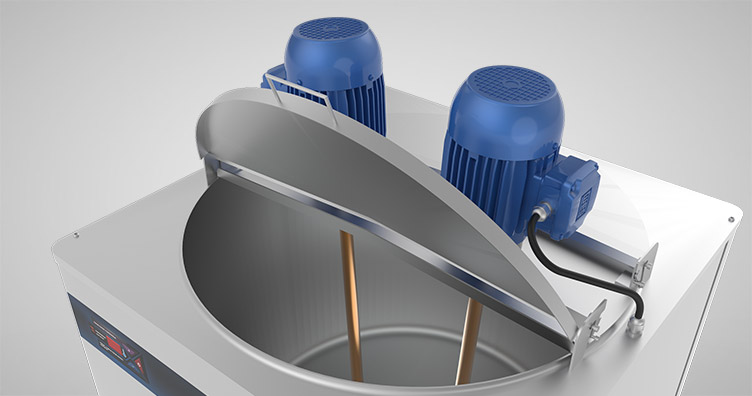

Easy to clean: removable lid, bottom inclines for complete drainage of the mixture, removable tubing and tap for cleaning.

Economizes energy: A closed gas heating system means lower power consumption than similar machines on the market.

High-quality pasteurized mixture: A homogenization helix with a unique system that uses a large perimeter edge.

Easy to operate: Programmable temperatures of 80ºC (176°F), 65°C (149°F), or whatever heat level is required. Aging (maturation) time can also be set according to need.

Maturation process starts automatically at 4°C / 39.2°F and can continue all night long (if desired), so the pasteurized and matured mixture would be ready to produce the next morning or just few hours after the cycle is completed (minimum recommended aging time is 2 hours).

Durable: Has a blender helix and a hardened shaft to endure large loads. Also has a compressor protection system and safety release valves for the heating process.

*Production depends on the climatic conditions of the location where the machine is installed.

Business purpose

For medium-sized ice cream producer who want to obtain industrial quality ice cream free off toxic bacteria. It is also useful for those interested in distributing their own products, since the pasteurization process greatly increases a product’s shelf life.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

1 PP200 + Super C.

1 PP200 + 1-3 Turbo25 popsicle machine.

1 PP200 + Turbo80 popsicle machine.

2 PP200 + C Max continuous freezer.

1. Pasteurized mixtures greatly increase air incorporation during the ice cream and popsicle production process. Increased profits alone pay for the equipment in no time at all.

2. Less ingredients are necessary, such as stabilizers and flavorings, since pasteurization increases the mixture’s capacity to absorb them. Reduced costs of ingredients also helps to pay off the equipment quickly.

3. Ice cream quality is guaranteed to be higher: not only is it more hygienic, but also provides better texture, flavor, color, aeration, time of conservation, melting resistance, and others qualities easily noticed by finicky consumers.

4. The outlet valve is 100% sanitary; no stationary mixture stays inside during the pasteurization process. Conventional valves retain liquid inside their parts, causing mixture RECONTAMINATION at the end of process.

5. Easy to wash and clean, has rounded edges and special materials, meets 100% of international sanitary standards.

6. Easy to operate and safe.& An automated start and stop operation avoids burning the mixture or delaying pasteurization.

7. Easy to transport due to its reduced dimensions.

8. On board computer, specific programs for each product to be pasteurized, adjustments for each stage of the process.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.