*This machine is not certified by ETL/UL/NSF rules.

*Please check the laws in your country about food preparation before finish your purchase.

Features

- 110 liters / 29.06 gal of pasteurized mixture in less than two hours.

* Production depends on the climatic conditions of the location where the machine is installed.

- Indirect heating (avoids burning ingredients) up to 85ºC / 185°F, in 55 minutes.

- Direct cooling (thermal shock) from 85 to 4ºC (185°F to 39.2°F), in 55 minutes.

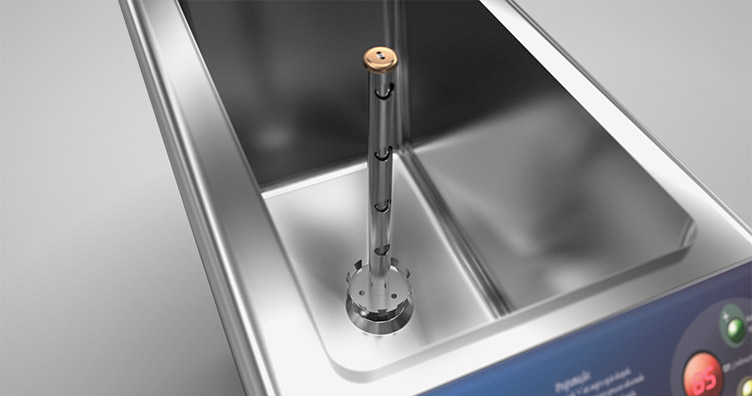

- Emulsifier/homogenizer at the bottom of the tank (100% sanitary).

- Special helix with wide cutting perimeter to diminish the size of particles.

- Double inclining tank, 110 liters / 29.06 gal capacity. Inner and outer rounded edges.

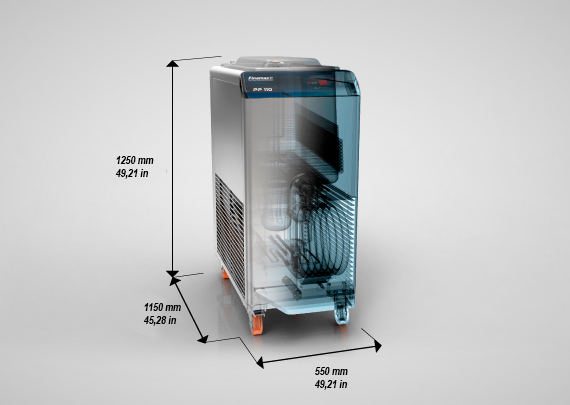

- Polycarbonate lid. Exclusive design.

- Temperature sensor immersed in the mixture.

- Tilted front panel with side handles.

- Self-cleaning exit valve, easy to disassemble.

- Container (bucket) support easy to disassemble.

- Eliminates toxic micro-organisms from ice cream and popsicle mixtures.

- Improves consistency, taste, and shelf life of the final product.

- A 4ºC aging cycle for up to 72 hours.

- Electronic controls allows the selection of other pasteurization temperatures.

- Three-phase 220/380V, 50/60Hz.

- Electric or gas heating.

- Uses tropicalized refrigeration and ecologic gas.

- Water condensation through use of a cooling tower.

Business purpose

For small to medium producers who intend to obtain industrial quality ice cream free of toxic bacteria. It is also important for those interested in distributing their own products, since the pasteurization process greatly increases a product’s shelf life.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

1 PP 110 + 1 to 3 Pro 16 Plus batch freezers.

1 PP 110 + 1 to 5 Turbo 8 popsicle machines.

1 PP 110 + 1 Super C continuous freezer.

2 PP 110 + 1 C Max continuous freezer.

1. Pasteurized mixtures greatly increase air incorporation during the ice cream and popsicle production process. Increased profits alone pay for the equipment in no time at all.

2. Less ingredients are necessary, such as stabilizers and flavorings, since pasteurization increases the mixture’s capacity to absorb them. Reduced costs of ingredients also helps to pay off the equipment quickly.

3. Ice cream quality is guaranteed to be higher: not only is it more hygienic, but also provides better texture, flavor, color, aeration, time of conservation, melting resistance, and others qualities easily noticed by finicky consumers.

4. The rectangular tank uses 40% less space than an equivalent round tank. It also avoids the inappropriate mixture of the ingredients, very common in round tanks.

5. Only a few machines like PP110 can reach 85ºC / 185°F, the temperature needed to eliminate 100% of toxic bacteria. Equivalent equipment from our competitors can only reach 70ºC.

6. The blending motor resides underneath the tank - 100% sanitary. Blending motors located above the tanks allow impurities to enter into the process.

7. The outlet valve is 100% sanitary; no stationary mixture stays inside during the pasteurization process. Conventional valves retain liquid inside their parts, causing mixture RECONTAMINATION at the end of process.

8. Easy to wash and clean, has rounded edges and special materials, meets 100% of international sanitary standards.

9. Easy to operate and safe. An automated start and stop operation avoids burning the mixture or delaying pasteurization.

10. Easy to transport due to its reduced dimensions.

11. On board computer, specific programs for each product to be pasteurized, adjustments for each stage of the process.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.