*This machine is not certified by ETL/UL/NSF rules.

*Please check the laws in your country about food preparation before finish your purchase.

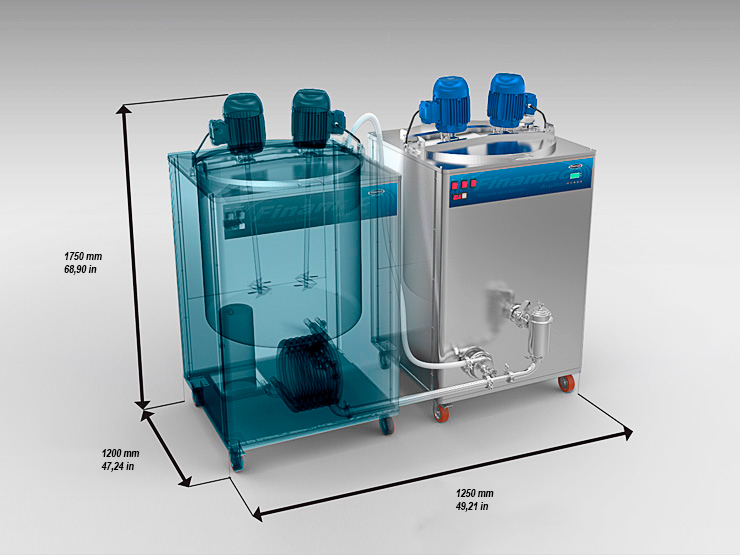

The Pasto Plant 300 facilitates the pasteurization process of ice cream and popsicle mixtures.

It eliminates unnecessary items used by small/medium production lines - saving energy, time, space, and cleaning products.

The heating tank heats the mixture up to 75ºC / 167°F, then it is abruptly cooled to 4ºC / 39.2°F in the cooling tank, eliminating the toxic micro-organisms found in milk and other ingredients.

The use of two tanks allows the heating and cooling processes to happen simultaneously, which means that a second mixture can be prepared while the first is being cooled.

Pasteurization does not only assure a healthy/safe product, but also increases the mixture’s capacity to absorb air and stabilizers, which results in a much softer and stable ice cream.

*Production depends on the climatic conditions of the location where the machine is installed.

Business purpose

For small and medium, industrial and semi-industrial ice cream producers who want to professionally increase their production with a high-quality final product assured through fast and efficient pasteurization.

Mixtures of 250 liters / 66.04 gal and more, to be used with compatible continuous ice cream freezers or popsicle machines.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

1 Pasto Plant 300 + 1 C Max.

1 Pasto Plant 300 + 3 Super C.

1 Pasto Plant 300 + 1 Super C3.

1. Reduces costs through simple and efficient production processes. No similar product on the market today performs all of the functions of the Pasto Plant 300.

2. Energy savings: independent heating and cooling tanks efficiently uses thermal energy and significative reduces pasteurization time.

3. Saves time with fast and easy cleaning: tanks are cleaned with a chlorinated solution and detergent, efficiently and perfectly sanitizing them. Tanks can incline up to three degrees, for easy and complete product/water drainage. Has rounded edges to avoid product or residues from accumulating after cleaning.

4. High production: 250 liters / 66.04 gal of mixture per hour effectively pasteurized.

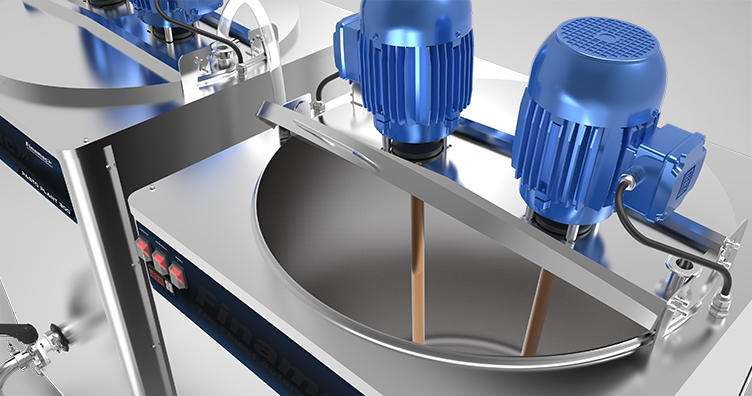

5. Industrial homogenizer not required: The heating and cooling modules have a helix that uses a high rotation and large cutting surface area, this allows higher particle breakage through a whirlpool effect.

6. Multi-plate heat exchanger and water cooler are not required due to an autonomous cooling module.

7. Pasteurized ice cream guarantees higher quality, not only is it more hygienic, but also provides better texture, flavor, color, aeration, time of conservation, melting resistance, and others qualities easily noticed by finicky consumers.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.