This kit consists of:

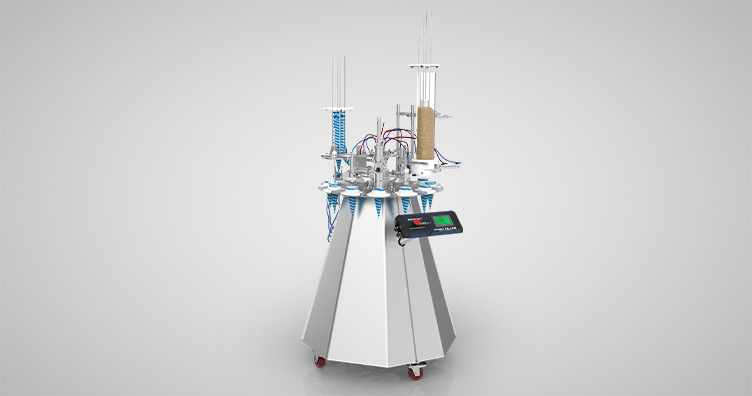

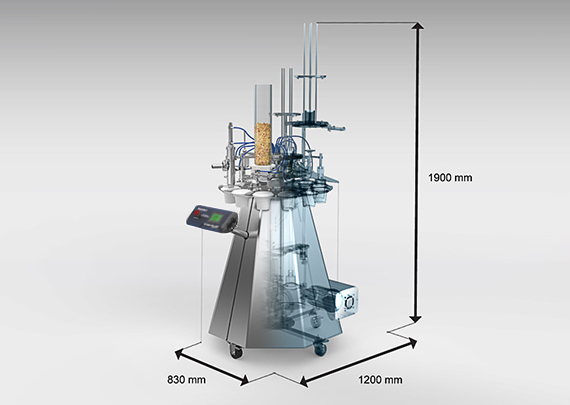

Super C Plus:

The acai is produced uninterruptedly, differing from machines that produce acai in predetermined quantities per beat. This means that it is not possible to make small quantities of acai with varied flavors. Once the production process is determined, this machine produces the only one flavor of acai, until the container from which the mixture is being withdrawn is emptied.

Other than continuous production, this equipment includes a pump which incorporates air into the acai while it is being beaten and frozen. Only with this process is it possible to obtain aeration levels (over-run) up to 30%. You may notice, in big acai trademarks, that the acai container only remains half full when it is melted. The explanation is simple: when melting, the acai loses the air which had been incorporated - half of the volume is composed of air.

Acai quality: Two horizontal cylinders with a high speed dasher, the same system used by acai industries around the world, assures finer texture and keeps ice crystals from forming.

Incorporated air (overrun): Up to 30% in acai production and 120% in ice cream production, with a working pressure from 2 to 10 bars, which allows connections to fruit feeders, dispensers, or automatic filling machines for cups, sundaes and containers, without losing pressure - assuring stability and perfect aeration during the dosage.

Defrost gas injection: Decreases production to 250L / 66.05 gal/hour.

Refrigeration: Uses tropicalized refrigeration and ecologic gas, water condensed.

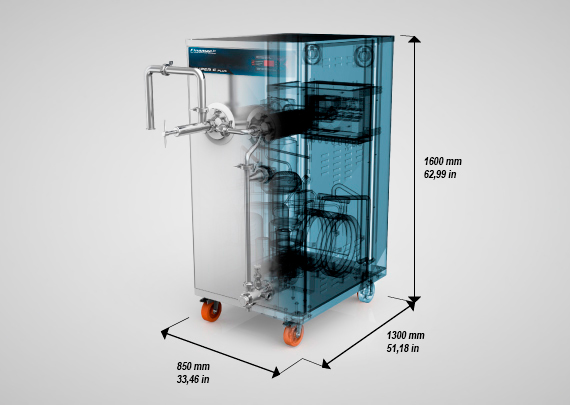

Gyrofiller:

This automated machine is designed to pack and fill ice cream and acai containers. Connected to a continuous freezer, the Gyrofiller pours the correct quantity of acai into various types of containers, like sundae type cups to various sized cups up to 2 liters / 0,52 gal.

It has automatic dispensers for the containers and their respective lids, as well as a device to print the production and expiration dates. It can also be equipped with dispensers for chocolate, toppings, and granulates.

Features:

- Packing volume of 90 ml to 2 liters / 0,52 gal.

- Ideal for packing liquids and pastes with application in the chemical, food, and cosmetics industries.

- Speed and packing volume are controlled electronically.

- Perfect synchronism, servodriven by microprocessor.

- For medium size producers who need practical equipment that take up very little space. For those who need to obtain automatically-packed, industrial-quality acai with a controlled production cycle.

*This machine is not certified by ETL/UL/NSF rules. Please check the laws in your country about food preparation before finish your purchase.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

Business purpose

For acai makers with some experience who wish to improve the quality and profitability of their products. In general, the Super C is usually used by acai producers that supply shops and other sales locations.

1. Substantially increases profits by incorporating up to 30% more air in the acai and 120% in ice cream production.

2. Substantially increases the quality of the acai, since the high-pressured aeration and beating improves the texture, taste, and stability of the final product.

3. Much higher production speed than traditional batch freezers.

4. Economizes ingredients because the whole process is done under high pressure, which makes it easier to mix and produce acai. Conventional machines, that don’t use a pressure pump, must use larger quantities of ingredients to produce the same effect.

5. It is the only machine that uses a cylinder where the acai is beaten - the same technology used by the Aerospace Industry. It is a thin cylindrical wall of extremely compacted material that substantially increases the freezing capacity. This special high precision cylinder is only available from Finamac.

6. Easy to operate, install, and transport.

7. The highest rate of production among machines of equivalent capacity and function.

8. Produces high quality industrial standard acai; not only more hygienic, but also with better texture, taste, color, aeration, time of conservation, melting resistance, and other characteristics easily noticed by discriminating consumers.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.