This kit consists of:

Pro 16:

A semi-automated machine that produces acai. This process is known as “discontinuous” or “batch” freezing. In accordance with these terms, we put a limit on the quantity of mixture used per cycle, differing from the continuous process, in which the mixture is continuously introduced through one side, and the acai comes out of the other side.

Production: 100 up to 120 L / 26.42 up to 27 gal/h (Production depends on the climatic conditions of the location where the machine is installed).

Energy saving: The dasher system is designed to work continuously, avoiding motor restart between each acai extraction. This procedure saves 20% energy compared to equipment with traditional dashers.

Acai quality: Soft and creamy, a triple dasher allows the acai extraction.

Higher profitability and more time to manage your business: Has an electric display for temperature control and easier operation. It does not require a specialized operator.

Safety and hygiene: The machine shuts off when the tilting frontal lid is accidentally opened. Lid easy to mount, dismount, and clean.

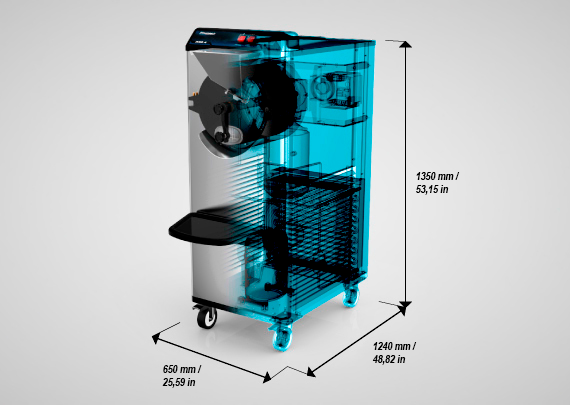

Fruit Mixer Açaí:

Equipment for crushing and homogenization of açaí.

Features:

- Capacity from 80 up to 500 liters / 21.13 up to 132.09 gallons of açaí;

- Mince and emulsifies açaí;

- Mix ingredients for formulation of ice cream, popsicles and creamy acai;

- Easy to operate, easy to install, easy to carry and move because it is on wheels;

- Rectangular container for easy cleaning and sanitizing;

- Propeller with great cutting perimeter to reduce particle size;

- Tap self-cleaning easy disassembly;

- Supply 220 V or 380 V three-phase.

*This machine is not certified by ETL/UL/NSF rules. Please check the laws in your country about food preparation before finish your purchase.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

1. The Pro 16 produces acai to be served on site, but also supports extra-production for acai distributed in containers to candy and other acai shops.

2. With a relatively low investment, this system´s production pays for itself in a short period of time.

3. The acai quality is incomparable, because all of the high-end technology used in large machines is also applied in this machine, at reduced costs.

4. It allows small quantities of acai production per beat, very important for people that work with a variety of flavors.

5. The acai is produced in few minutes, avoiding the formation of ice crystals and the undesirable “sandiness” caused by the traditional sluggish equipment.

6. Previous knowledge about acai production is not required. Easy to operate, install, and transport.

7. Maintenance can be done by a domestic refrigerator technician.

8. The best production/time rate among equivalent conventional equipment.

9. The acai made with Pro16 is guaranteed to be better: not only is it more hygienic, but also provides better texture, flavor, color, aeration, time of conservation, melting resistance, and others qualities easily noticed by finicky consumers.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.