Strawberry pulps, caramels, syrups, etc., are difficult to mix smoothly into ice cream. They also increase the water level in the ice cream and harden while freezing. The reason for this difficulty is that aerated ice cream is produced under elevated pressures; he introduction of pulp under these conditions is a difficult task.

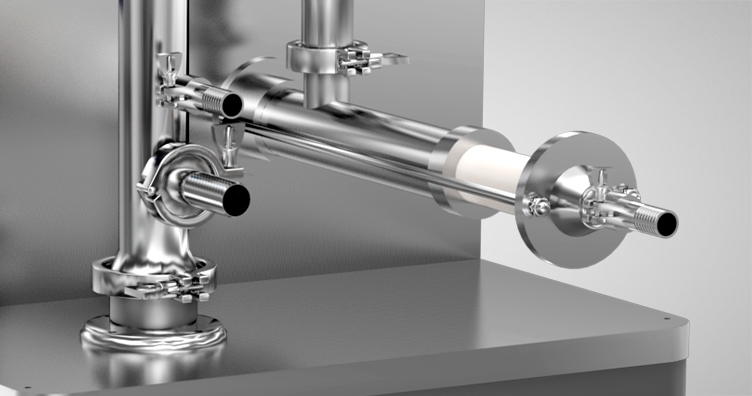

Finamac™ incorporator was developed not only to introduce these ingredients into the ice cream, but also to maintain pressure in the tubes, allowing a smooth connection to automatic filling/packing machines.

The ice cream comes from a continuous freezer and passes through the incorporator; then, it is directly conveyed to a packer. The incorporator has the difficult job of introducing pulps into the ice cream under high pressure.

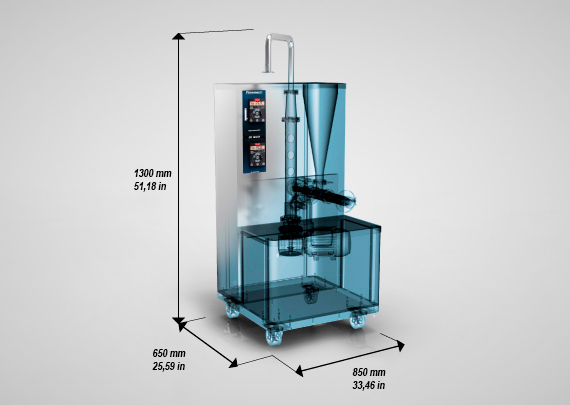

* The production depends on climatic conditions and installation of the places where the machine is located.

Some products produced with a pulp incorporator are:

- ‘Marble coloring’ effects in the ice cream;

- Toppings;

- Condensed milk;

- Chocolate syrup;

- Other diverse syrups;

- Fruit ice cream with incorporated pulp (strawberry, pineapple, raisins in rum);

- Flaked ice cream with a melted chocolate mix;

- Sundae cups;

- Cones and other creative concoctions.

*This machine is not certified by ETL/UL/NSF rules.

*Please check the laws in your country about food preparation before finish your purchase.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

Business purpose

Small, medium and large ice cream industries with experience in continuous production line. This equipment is essential for the production of ice cream with strawberry pulp and many others.

1 IX 600 + Super C

1 IX 600 + Super C + GyroFiller

1. Allows regulations for quantity and mixture homogeneity levels.

2. Adjusts from small quantities of ice cream to high levels of production; working with only one small-sized freezer or many freezers at the same time - or, if you want, only one large-sized freezer.

3. Uses the latest technology for introducing pulp into ice cream.

4. Ice cream mixed with high pressure has higher quality - not only is it more hygienic because there is no contact with the air outside of the machine, but it also produces better texture, taste, color, aeration, time of conservation, melting resistance, and other characteristics easily noticed by discriminate consumers

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.