It consists of:

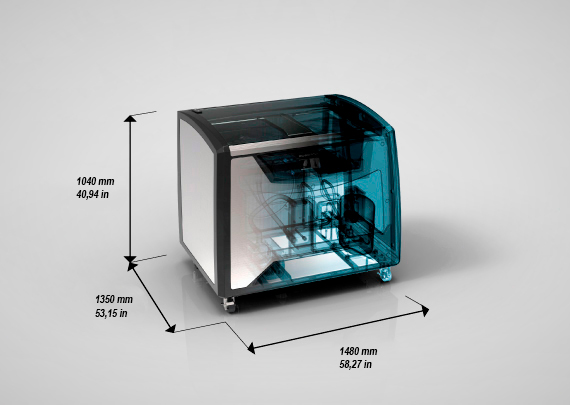

Flex Mixer Blender/Emulsifier:

The new Flex Mixer line was developed to prepare mixes for handmade ice cream and ice pops, making them very attractive to the final consumer for being clearly smoother and creamier. This differentiated quality is obtained by reducing (micronizing) the ingredients' particle size and by incorporating air into the mix.

Robopop Start or Robopop Ultra:

With bold design, it allows to produce ice pops in sight of consumers, with visual elegance and total hygiene.

Sealing machine for ice pops packages:

Used in various segments, this is a pedal sealer, whose capacity is 20 cm / 7.87 in of sealing. With metal busbar, it is recommended to seal transparent polypropylene plastics, laminated, bioriented, among others. It has several advantages, including the fact that it is economical, consuming an average of 0.30 Kw/h

Observations:

* The equipment with air condensation has a reduced production of 10% to 50%, from an ambient temperature above 28ºC to 45ºC / 82.4°F to 113°F.

* The production of the equipment depends on the climatic and installation conditions of the places where the machine will be located.

* Images merely illustrative. The quantity and type of molds may vary, as well as the model of the demolder.

* EQUIPMENT FOR INDUSTRIAL USE

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

Who is it intended for

For small and medium entrepreneurs, who are starting or growing in business, or professionals who want to increase their production in a modular way, adding more than one machine as production needs increase.

For those who need to reach the industrial quality standard of popsicles, even in small quantities, with controlled production cycle.

Ice cream/pickle shops, small ice pops industries, small retail stores and various types of food stores can easily install this equipment in their facilities, with a simple operator training.

Thanks to its innovative design and refined technical features, the high quality of the popsicle produced by Robopop and its presentation meet the needs of the most demanding consumers in high level premises.

A complete package that allows the manufacture of ice pops, enabling the production of several products, such as skimo, mini skirt, napolitano, decorated popsicles, etc.

With the acquisition of accessories other products can be manufactured: ice cream candies, moreninha, ice cream without toothpick and with different shapes models.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.