During the past 50 years, few significant innovations have emerged in machine technology for producing artisanal ice cream.

Most of them have concentrated on the electronics of the equipment, and even then, the functions remain the same.

It's simple. A freezing cylinder, a mixer, a lid and some functions that detect when the ice cream is ready.

Competition among ice cream machine manufacturers have remained restricted on tradition only, based on "who has created the first machine", or on the launching of small construction details that have added little or nothing to the end result of ice cream produced.

All machines have never lost the appearance of “the square box style" and have kept exactly the same design standards for many years. A metal frame covered by steel folded sheets and that’s it.

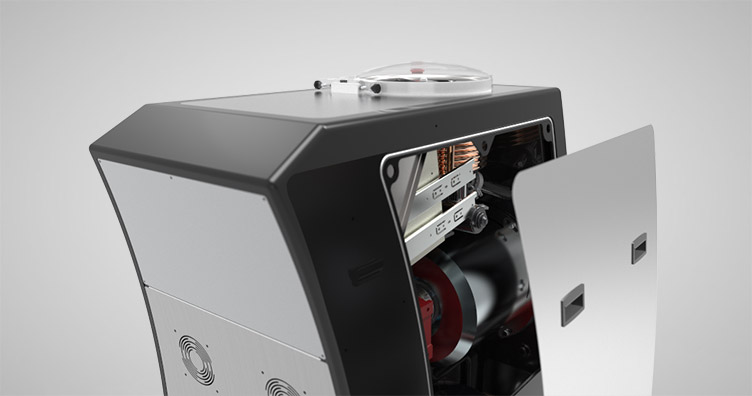

The ICE CLEAN line is the result of an observation and study throughout the years to break the current design of equipment for pasteurization and ice cream production in the world.

The name CLEAN stands for the cleanliness of the components and the design. ICE CLEAN refers to ice cream, clean, sleek and healthy, in every way.

Developed with fluid dynamic computer simulations, provides the following advantages:

- Its shape and rotation spread the liquid mixture all around the freezer cylinder, reducing the time it takes to freeze the ice cream.

- Blades supported on springs remove thin layers from the ice cream formed in the cylinder wall mixing it with the remaining liquid part.

- The incorporation of air in ice cream is precisely done to achieve high levels of consistency and creaminess.

- Quick ice cream extraction at the end of the freezing, allowing the inside of the cylinder virtually clean.

- Smooth finishing facilitates cleaning, maintenance and handling.

- Energy saving of the motor that moves it.

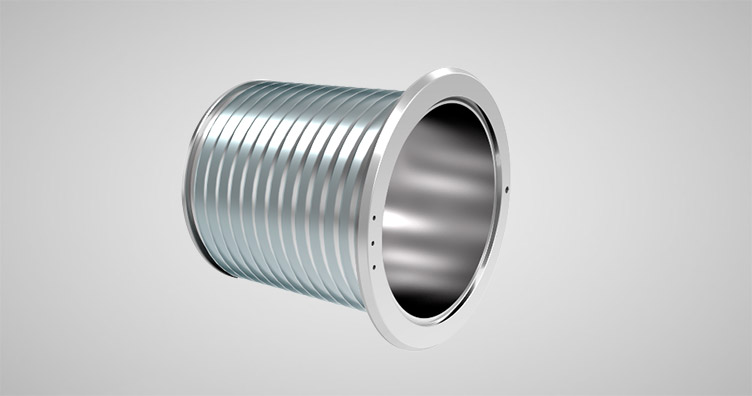

Ice cream freezing cylinders have been made of thick material for many years, without any control over the freezing process.

The ICE CLEAN cylinder is made with a thin and strong wall, which significantly increases its ability to freeze, reducing production time and power consumption. The decrease in production time results in an ice cream with much finer granulometry than the conventional kind.

It is breaking a paradigm, because some machine manufacturers believe that the thick wall cylinders are robust, when actually they are inefficient and carry excess material, without any technical function.

Control of cold was never taken into account by conventional machines. Just pour the maximum cooling power around the cylinder, as cooking food at high heat. Just as food can be burned, the ice cream can also "burn" with excessive cold.

In ICE CLEAN the cold intelligently operates on each stage of ice cream production and also in its extraction. If the cylinder has less ice cream or is almost empty, we should not super freeze the mixture that is in it. Thus, the ice cream does not lose flavor and energy consumption decreases.

Made of a special food grade plastic, prevents heat loss and the formation of water droplets on its outer wall, (very common in conventional metallic lids). The plastic also eliminates the adhesion to rubber seals.

The entry of ingredients is done by a large and detachable funnel, facilitating cleaning of the parts. The ice cream outlet is controlled by a sliding hatch without pivotable arms and difficult to clean parts, very common in conventional lids.

The complete lid opens up horizontally and is easily removable from the equipment, facilitating cleaning.

Pasteurization of ice cream or milky mixtures is usually made in separate equipment from the batch freezer. ICE CLEAN P combines this into a single device, an upper cylinder to heat the mixture and a lower cylinder to beat and freeze the ice cream.

This combination is very advantageous because it allows small amounts of pasteurized mixture (4 to 8 liters / 1,05 to 2,11 gal per turn) to be pasteurized, while the production of separate pasteurizing tanks have capacities starting from 60 liters / 15.850 gal.

ICE CLEAN P is equipped with a digital heating system in its upper cylinder, which does not burn the mixture.

Conventional heating systems usually exceed the maximum temperature and burn the components of the formula.

In ICE CLEAN P both the wall around the cylinder and the bottom are heated, minimizing the total time to heat the mixture. It is a very fast and soft heating system, unique in the market.

With self-adjusting scraper blades, both on the side wall of the cylinder and on the bottom, the mixing system ensures that no part of the liquid is left unheated or stays in contact with the hot walls for too long.

Two blades attached to the mixer uniformly distribute the components of the formula around the cylinder so that no regions are formed in which there is no sufficient agitation.

The drainage of the heated mixture can be made directly into the input funnel of the ice cream batch freezer through an electric valve. Conventional machines have a drain inside the machine, which causes difficulties in the cleaning process and the independent use of the upper cylinder.

Moreover, the rotating tap allows the independent use of the upper cylinder, by simply rotating it for discharging the heated mixture into a side recipient.

ICE CLEAN line represents the end of the "square box style" machines. Here ends the concept that the machine needs to be hidden from the public view because it is ugly, clumsy and dirty looking.

Its structure is made of composite material with rounded edges and stainless steel panels without folds and screws, resting on rubber gaskets to ensure sealing for cleaning and noise insulation. Its resistance is superior to steel, its weight is very light and can be supplied in a set of colors, especially for the standardization of franchise chains.

With a panel of tempered glass and "soft touch" buttons, the design forms harmonious and clean lines with a strong visual appearance, allowing it to be seen by the end-consumer and not placed in a back room.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

For entrepreneurs of Italian gelato and premium ice creams, who only produce high quality products where the exposure of the equipment is part of the business, that aim for a strong visual and qualitative impact.

1 ICE CLEAN + 1 PP 60 or PP110, for pasteurized gelato production.

1 ICE CLEAN P + 1 or 2 Finamac display cases.

1 ICE CLEAN P + 1 CLEAN (version without pasteurization).

1 ICE CLEAN P + 1 ice pop machine model Robopop Start or Ultra. To produce high quality aerated ice pops.

1 to 3 ICE CLEAN P, for modular ice cream production increase.

1. You will produce creamy ice cream and not "thick" ice cream. What does this mean? The final product exits the machine with extremely small particle size and almost all water in the mixture will be frozen, providing a completely smooth cream without any "grains" (small ice crystals), consistent and at the same time, extremely soft. Making it impossible for your customers not to take one more ice cream. The difference is great and very easily noticed.

2. Pleasant tasting: the ice cream does not require post freezing and can be placed in basins to be decorated and served right away. Its firm consistency ensures greater resistance to melting, so customers can taste it carefully without hurrying.

3. Production of ice cream with 100% natural ingredients, which usually require greater cooling and beating capacity.

4. Control of air incorporation in the mixture, enabling the production of gourmet/premium ice cream or lighter, with high quality standards.

5. Small or large quantities of ice cream per turn, very important for anyone who works with many or few flavors.

6. High-level ice cream, high-level equipment. All parts in contact with the ice cream and the construction of the machine as a whole strictly follow international standards of hygiene and safety.

7. Ice Clean P model: pasteurization, beating and freezing process in a single machine, ensuring 100% quality and safety of the final product.

8. Ice Clean P model: possibility of using the mixture heating cylinder to feed other ice cream batch freezers or other purpose equipment, independently.

9. Ice Clean P model: pasteurization ensures greater absorption of the ingredients contained in the formula, more stable air incorporation in the mixture and the total safety of absence of harmful micro organisms at the resulting ice cream.

10. Attractive and functional look. Producing ice cream in front of the customer increases by 30% the amount of people within an ice cream parlor. The visual set of ICE CLEAN is designed to go beyond that, creating a strong consumer identification with form and appearance which the ice cream is produced.

11. Ecology and sustainability. Equipment with low noise, ecological cooling system, recyclable materials, lightweight, reusable crate.

12. Efficiency: lower rate of energy consumption per pound of ice cream produced, all heat generated by the equipment is conducted through a single output, avoiding environment heating and ice cream cooling efficiency losses.

13. Operation and maintenance. Operation by soft touch buttons on tempered glass panel, which command an intelligent electronic device, makes ICE CLEAN a very easy machine to operate and with all alerts of preventive and corrective maintenance.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.