This equipment is used to automatically incorporate ingredients into continuously produced ice cream or açaí, increasing the added value of the final product and enabling the creation of new flavors in your product line.

It allows you to incorporate solids such as fruit, nuts, crunch, hazelnuts, flakes (chocolate chips or shavings), fruit pulp and other ingredients into the ice cream. The ice cream comes from a continuous mixer and the solid ingredient or pulp comes from the equipment's reservoir.

The equipment consists of:

Ingredient tank with a capacity of up to 30 L of product:

VOLUMETRIC DOSER - A rotor consisting of a piston with double volumetric dosage per revolution applies the ingredients to the ice cream in the continuous line, without human contact. Ice cream mixed at high pressure is superior in quality, as well as in texture, taste, color, aeration, shelf life, resistance to melting and other characteristics easily perceived by the most exigent consumers.

Our system has the following advantages over other equipment on the market:

More uniform dosing, making it easier to adjust the quantity and distribution of items in the ice cream;

The special design of this mixer allows the ingredients to be distributed evenly and reduces the temperature loss of the ice cream.

Our customers often point to this DOSER/INCORPORATOR combination as the most efficient on the market today.

Our equipment has been designed to allow total freedom of creation and ease of control, making it possible to use most of the ingredients the customer wants.

This is achieved by controlling the speed of the 3 devices:

Independently, making the necessary adjustments during production extremely simple.

The freedom to use solid particulate ingredients or fruit pulp with generous chunks is one of the IF 900's greatest advantages.

In addition to all these benefits, we can also attach a syrup incorporator to the equipment's outlet, like the IX 600, and create other products by mixing the syrup into the ice cream with added ingredients.

Made from 304 stainless steel, using components from world-renowned brands, constant operation,

ease of maintenance, compact size and unrivaled reliability are guaranteed!

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

Business purpose

For small, medium, or large sized ice cream companies that have experience in continuous lines of production. This equipment is used for chocolate flakes, cream with raisins, flavors with chestnuts, granulates in general, strawberries with pulp, and much more.

1 IF 900 + from 1 to 4 Super C

1 IF 900 + from 1 to 4 Super C + GyroFiller

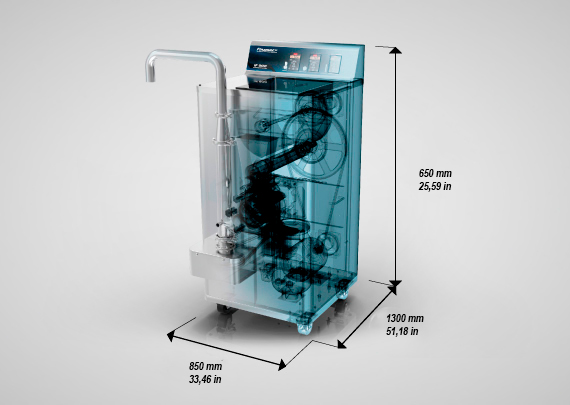

1. Occupies 60% less space than conventional fruit mixers.

2. Allows settings for quantity and mixture homogeneity levels.

3. It can be supplied solely for syrup incorporation (economical version).

4. Uses the latest technology for introducing solid ingredients into ice cream.

5. Ice cream mixed with high pressure has higher quality - not only it is more hygienic because there is no contact with the air outside of the machine, but it also produces better texture, taste, color, aeration, time of conservation, melting resistance, and other characteristics easily noticed by discriminate consumers.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.