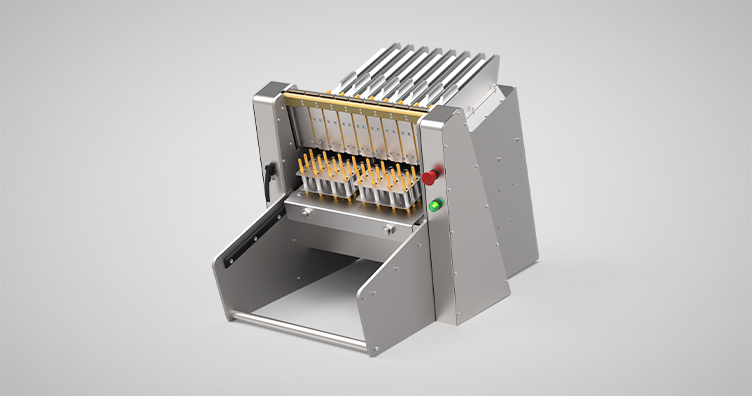

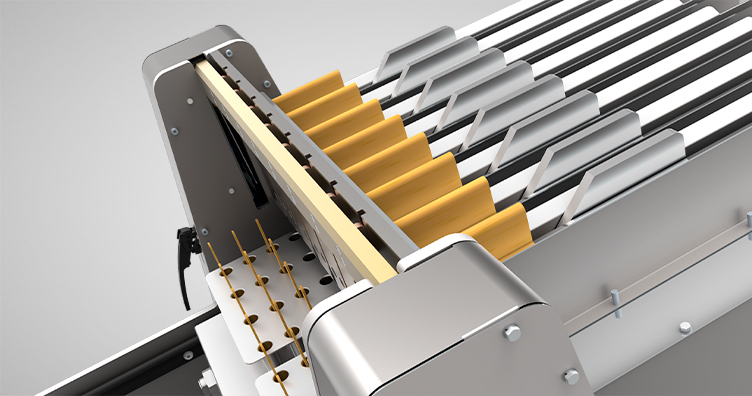

The aligner is placed on this device to allow the popsicle sticks to be positioned sequentially and automatically, eliminating manual labor.

It is 90% time-saving, decreasing the need for more people in production. To do this, simply feed the equipment with sticks and start the machine.

Thus, with sticks quickly placed on the aligner, the equipment operator will hold them (already aligned) in a device called a "puller" and enter them in their popsicle molds, to be dipped in alcohol or glycol for freezing.

After freezing the sticks will be stuck and simply remove the popsicles in fashion.

The total production time drops sharply without the need for additional manpower. The manual process of inserting sticks in the aligner without the help of this equipment is time consuming, painstaking, repetitive and occupies much of the time needed to works on the production line.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

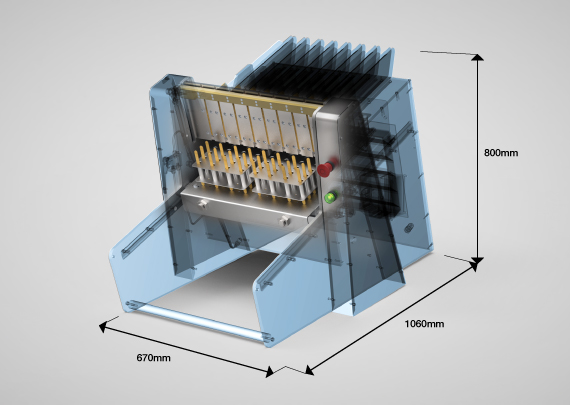

For popsicle production from 750 pieces / hour as TURBO 25, TURBO 80 e TURBO 100.

1. Accelerates the alignment of popsicle sticks.

2. Eliminates labor with only needing to feed sticks into the aligner.

3. For larger production of popsicles the time saved is essential.

4. It is an electrical apparatus with pneumatic automatic return, easy to install and use.

5. It successfully serves small and medium producers.

6. It is a guaranteed investment with a quick return.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.