This equipment will be available for sale in the 2st half of 2025

The taste of refreshment is on the rise with a novelty exclusively developed by the Finamac™ engineering team.

This new technological project will bring more customers to your business, increase your sales and profits, and deliver some innovation with a Frozen Drinks machine.

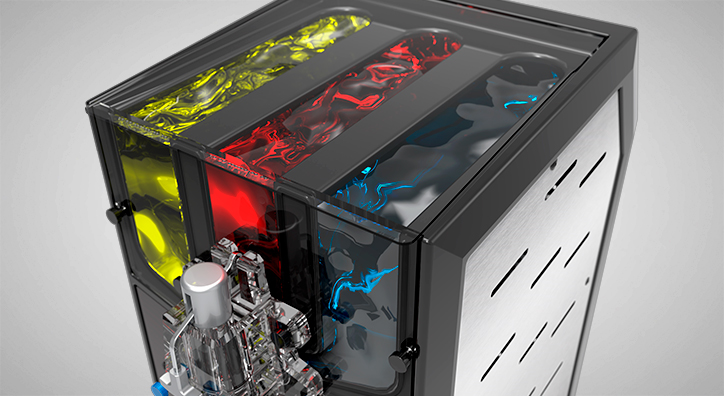

Produce traditional recipes for drinks based on whiskey, vodka, gin, tequila, cachaça, liqueurs, pisco, shakes, wines, etc., displaying your mixes elegantly in the Flash's 3 transparent tubs, which can help increase your sales by up to 30%.

Flash Drinks is a unique machine, created exclusively by Finamac™, a company that has been developing solutions for the ice cream market for over 30 years and is the largest manufacturer of machines in Latin America, exporting to over 110 countries.

There is no other equipment like this in the world.

Be part of this innovation: surprise your customers and overcome the competition!

With Flash your product is made on the spot.

At the moment of production, the quantity of mix is inserted in the beater cylinder, which is emptied at the point of drink extraction, in up to 30 seconds.

With Flash, the drink mixtures are visible to the consumer, thanks to its transparent front cover which allows to display with greater visual appeal the colors of the flavors in its 3 tubs, serving as a strong attraction for impulse purchases.

In addition to its intuitive engineering Flash was developed with a futuristic design of modern shapes, bold colors and quality materials.

The beautiful and elegant design will contribute to your business environment and attract costumers curiosity.

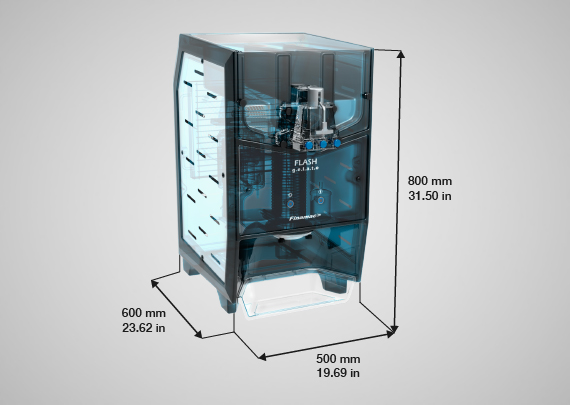

Flash is the lightest and most compact machine of its category in the market, developed so that you can commercialize your drink almost anywhere, occupying very little space, giving more versatility to the entrepreneur and being able to operate even in reduced spaces.

The Flash project reached extremely low costs for such a versatile machine and with such production capacity, resulting in the unprecedented technology developed by the Finamac™ team of expert engineers. Its maintenance also has a very low and incomparable cost.

Produce a much creamier frozen drink with the exclusive SHARK (Softening Hardness Aided by Rotating Knurling) scraping system, based on the profile and cutting power of sharks teeth.

Aside from reducing up to 30% the effort required to run the electric motor which moves the beater, it also uses teeth(scrapers) made of special materials. It is easy to disassemble/wash, and the use of springs is no longer required to keep the scraper pressed against the cylinder wall.

The frozen drink produced in the Flash is differentiated. This is possible thanks to its vertical stainless steel cylinder with high efficiency for the drink mix, made with the same technology used in the manufacture of rockets, which has a thinner wall thickness, enabling greater transmission of cold and fast freezing, without generating ice crystals.

The total weight of the Flash can be up to 30% lighter than conventional equipment. This is because the machine's cabinet uses the same technology employed in aircraft, with high resistance fiber composite material, without seams or corners for dirt to accumulate in food contact areas. Flash is a light but also robust piece of equipment, with its internal construction made of 100% stainless steel and composite material. Easy to disassemble for cleaning and maintenance.

Designed t0 always be well ventilated and aired, maintaining the machine's performance even in very tight environments, Flash has air inlets and outlets that prevent the flux of hot air. The internal part is easy to clean, avoiding contamination sources.

Enjoy sales on hot days and places with the Flash refrigeration power, developed so that there is always enough air flow to cool the machine, even in extreme temperatures and humidity.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.