The display cases were created to increase the sale of refined and freshly made ice cream, known as "gelato", a word that means artisanal ice cream in Italy, the country where the concept of presenting the product to the consumer with all the refinement it deserves was originated.

Practically all Italian cities are full of "gelato shops" and the display case plays an important role in creating a strong impact by displaying the colors of the gelato and its very attractive decoration.

Sales are estimated to have tripled compared to the old sales model, based on closed freezers that did not allow the product to be viewed. The concept of “gelato shops” began to be exported to all countries and still has a lot of room to grow.

Recently refined ice pops have begun to be exposed in display cases and have been an absolute success in several countries.

Impulse sales studies prove that humans literally "eat with their eyes". Several food sectors already have used the technique of exposing edible products such as candies near the store check out.

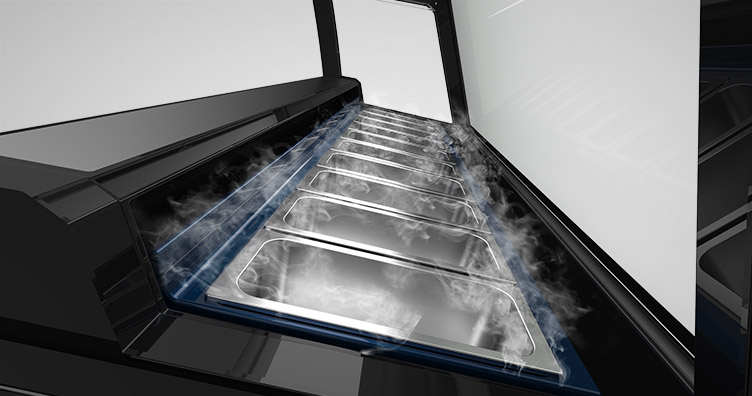

Because they are frozen products, ice cream and ice pops have a higher degree of difficulty to be exposed. Negative temperatures freeze the water contained in the air and end up forming a kind of snow around the walls of common freezers, just as ice is formed in freezers of domestic refrigerators.

The development of thermal (heated) glass was fundamental to solve this problem and allowed the creation of display cases for negative temperatures, dramatically increasing the field of visualization of ice cream and ice pops inside. The heating of the glass prevents internal fog and external condensation.

Allied with this great advantage, the design of the display cases is no longer a “crate like box design” and began to take on a much more elegant form that is consistent with the viewing pleasure that ice cream and ice pops offer.

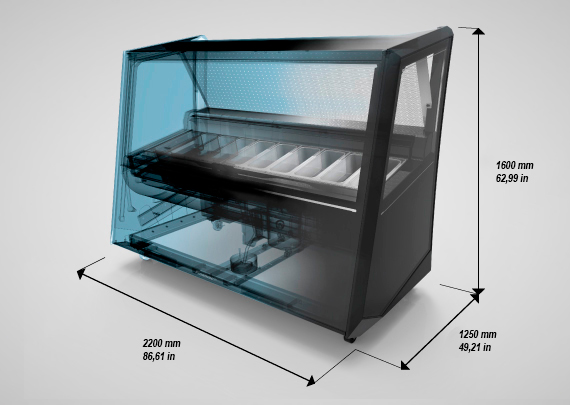

With sleek and pointed edges, the latest trend in the world, the Vista display case adopts the concept of sloping faces, both with its front and upper glass. In addition, the glass occupies the total area of the sides and front and does not have any seams, resulting in an unparalleled panoramic view of the exposed product, an absolute novelty in the market.

With various finishing patterns, it is possible to choose set colors and custom images for the front of the glass, ensuring greater sales power and business customization.

Special lamps highlight the colors of ice cream and ice pops, attracting visual attention even at great distances.

The Vista display case is the only one in the world built with thermally insulating materials both internally and externally. Inside there are two food grade plastic tanks, both without any seems and with thick thermal insulation. All corners are rounded and easy to clean.

The outer tank forms the structure of the display case and accommodates the inner tank, which contains the basins. The cooling system and the fans that generate the cold curtain are positioned between the two tanks. The inner tank is 100% removable and washable and the fans are 100% humidity and cold resistant, easily removable.

Conventional display cases have tanks made of metal folded sheets with sharp corners, which makes cleaning practically impossible; these sheets may be sharp and also impair the thermal insulation of the assembly. This option is used because it is more economical, but generally does not meet sanitary standards.

The sides of the Vista display case are made of high strength composite material used to support the two tanks mentioned above and the heated glass, ensuring an impeccable finish. All glass panels are fitted over rubber gaskets to prevent loss of cold.

The Vista display case is designed for both ice cream and ice pops. Because their lower (colder) freezing point, ice pops need a higher cooling capacity and different characteristics of the cold curtain that passes over them, which is why it is recommended to use a display case which is able to set different temperature settings for either ice cream or ice pops. Conventional display cases usually do not function properly to expose ice pops.

Display cases are divided into two categories: "ventilated” and "static". Ventilated means that there is a curtain of cold air passing over the exposed products, while the static ones do not have air in motion, as in common freezers of ice cream or ice pops found in bakeries or supermarkets.

In "static" displays the ice cream or ice pops must always be 20 cm / 7.87 in

below the glass, since there is no air curtain and the constant opening and closing causes the partial melting of the product. In this type of display the ice cream or ice pops are visible only when the customer is very close to the equipment.

In ventilated displays the ice cream or ice pops can be placed at a higher position, however always below the air curtain. This allows the product to be viewed by far distances. The Vista display case belongs to this category.

The heated glass used in display cases can be single or double.

In the single heated model consisting of only one glass pane, the ice cream needs to remain at least 10 cm / 3.94 in "sunk" inside the cabinet, compromising the product visibility from distance.

The double heated model is composed of two glass sheets, the internal one without heating and the external one with heating. Between them a special gas is injected, which helps on the thermal insulation. The ice cream can be displayed up to 15 cm / 5.91 in above the cabinet, causing a strong visual impact, and can be seen at great distances. Vista display case belongs to this category.

In the Vista display case the ice cream is accommodated in 12 degree forward tilted basins in order to increase the visibility and visual impact of the product.

The inclination of the ice cream makes it difficult to maintain its uniform temperature, requiring that the air curtain's effect be very well controlled. There are rare display cases in the world that achieve this precise control. Vista is one of them.

While most display cases have two rows of basins, Vista is designed with only one row, preventing the operator's arm from going over one row of ice cream to reach the second, ensuring total hygiene in the handling of the product.

In addition, work ergonomics are appreciably improved when there is no need for access to a second row, usually well away from the operator.

Given that the display case is the main point of the ice cream shop, the Vista project has chosen to have a large front display area of basins. The ten 5-liter / 1.32 gal basins accommodated by Vista are positioned in a 1.8 m / 70.87 in width, while an equivalent display case with two rows of 5 basins would be just 0.9 m / 35.43 in wide. The smaller the front of the display case, the smaller the attractiveness of the ice cream is inside your shop.

Because ice cream can be decorated up to 15 cm / 5.91 in above the basin, a single row also prevents a back row from not being viewed.

Refined ice cream or "gelato" needs to be served at the exact temperature and this is a great secret to your success. If the temperature is slightly above or slightly below ideal point, the ice cream will lose its maximum creamy consistency, which is a very important characteristic to satisfy the taste of the consumer. The same happens with ice pops.

The temperature of the glass also needs to be adequate to avoid fog on humid days.

The defrosting of the equipment is done automatically by a heat pump device, the most efficient system for this purpose and the only one capable of completely defrosting in a short time, without changing the characteristics of the exposed products. Conventional display cases have less efficient defrost systems (cheaper solutions), which force the user to turn off the equipment and withdraw the product for many hours, for complete defrosting.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

Gelato shops (Italian ice cream), ice pop shops, traditional ice cream parlors, bakeries, confectioneries, snack bars, sophisticated bars and restaurants and other establishments that seek high returns in the ice cream and ice pops of higher quality.

It applies to those who produce a wide variety of flavors and are located in places of greater movement, like shopping malls, street stores or other commercial points.

Establishments that intend to make their own ice cream/ice pops and replace the industrial ones, whose profit margin is low. Finamac Ice Clean P machine associated with a Vista display case make up an extremely lucrative business.

Franchise networks that seek a significant increase in financial returns, as an important complement to the products they already market or as the main product.

Complete Gelato and Ice pop store: 2 Vista display cases + 1 Ice Clean + 1 PP110 + 1 Robopop Start

Compact Gelato store: 1 Vista display case + 1 Ice Clean P

Complete Gelato store: 2 Vista display cases + 1 Ice Clean + 1 PP110

Compact Ice pop store: 1 Vista display case + 1 PP 60 + Robopop Start

Complete ice pop store: 2 Vista display cases + PP110 + Robopop Ultra

Increases sales by up to 30% and provides elegance and beauty to the environment.

Much lower investment than display cases with two rows of basins.

Smaller space (not very wide for having only a row of basins) and better use of it, since the area of exposure of ice cream and ice pops is maximum.

Lower energy cost per kg of ice cream or ice pop exposed due to the unique row of basins and the absence of metals inside the cold air circuit.

Great versatility of installation and operation, since Vista has casters that facilitate any changes of lay out and displacements for cleaning. Conventional display cases are usually fixed to the floor and do not offer this facility.

Easy to transport: very low weight due to the use of composite materials in its construction. Conventional display cases are very heavy because they are made with economical metallic structures.

Easy to maintain: the unibody construction of the tanks and the sides of the showcase allows more space in the lower part of the equipment, facilitating access to all components as well as a larger area for ventilation.

Resale value guaranteed because it is compact equipment of high production and equipped with state-of-the-art technology with all control systems included.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.