The set consists of:

1. Blender / Mixer Emulsor 15: With a capacity to beat up to 8 liters / 2 gallons of syrup, the mixer 15 is intended for small producers who are just starting out in this business, or professionals who wish to increase their production and profitability. Its patented helix leaves the milk mixture well homogenized and with a greater incorporation of air, causing softer popsicles and more profitable. Mixer 15 incorporates 10% - 20% of air into the mixture, providing greater efficiency in production and thus increases profitability. All these features guarantee top quality, not only in appearance, but also in texture, flavor, color, aeration, preservation, resistance to melting, and other features easily perceived by the most discerning customers. This device is easy to operate, install, and transport.

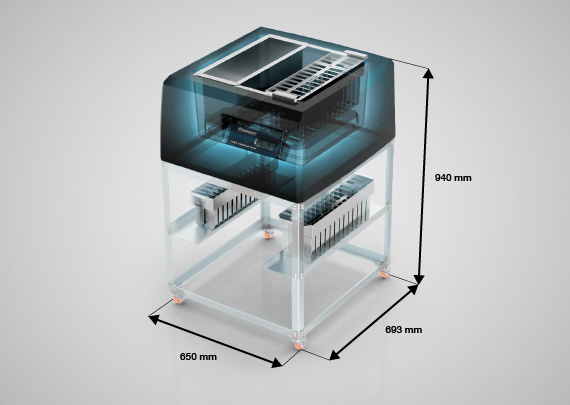

2. Producer Popsicles Turbo 25: A semi-automatic machine that manufactures water or milk-based popsicles, working with commercial three-phase energy.. The Turbo 25 helps many entrepreneurs start a promising business. It is also designed for professionals who wish for a modular increase in production, with the ability to add more equipment as needed. This machine occupies 60% less space used by conventional equivalent equipment. The Turbo 25 is unsurpassed when it comes to delivering successful results for experienced leaders in the ice cream industry. It is fast, convenient, and requires no prior knowledge about making popsicles. It’s easy to operate, install, and transport.

3. Flex Unmold Tank: It consists of a tank of warm water where the ice pops are placed for a few seconds and the temperature is controlled electronically. The thermally controlled process of the ice pop mold being dipped into the tank for a few seconds causes a heat shock that

allows the ice pops to be loosened from their molds almost instantly.

The tank can be used with or without a stainless steel base (optional). If used without base, it can be placed directly on a workbench or used as a table top.

4. Sealing: A compact machine used in several segments. The treadle drive leaves your hands free to work with the products. Has the capacity seal up to a width of 20 cm / 7.87 in. Works well with clear polypropylene plastics, laminated, bio-oriented, etc. It has several advantages, such as being extremely economical - it only requires an average of 0.30 kW / h.

5. TR 5/10: Water cooling tower It is an indispensable accessory that removes the heat generated by machines used to make ice-cream and popsicles.

Provides maximum performance to your ice-cream/popsicle machines, even on the hottest days and prolongs life of equipment by maintaining good working condition within controlled temperatures.

*Production depends on the climatic conditions of the location where the machine is installed. Depending on the shape mold brand, the machine capacity can range from 9 or 10 28-cavity shape molds.

* Images merely illustrative. The quantity and type of moulds may vary, as may the model of the unmolder.

*Please check the laws in your country about food preparation before finish your purchase.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

A complete set of machines for manufacturing ice pops. It also provides the ability to produce various other products, such as skimo, half chocolate coating, Napolitan (3 flavours), and decorated popsicles.

With the addition of just a few accessories, several more products can be made: ice cream bonbons/chocolate coating, free stick ice cream, and models with different shapes.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.