It has automatic dispensers for the containers and their respective lids.

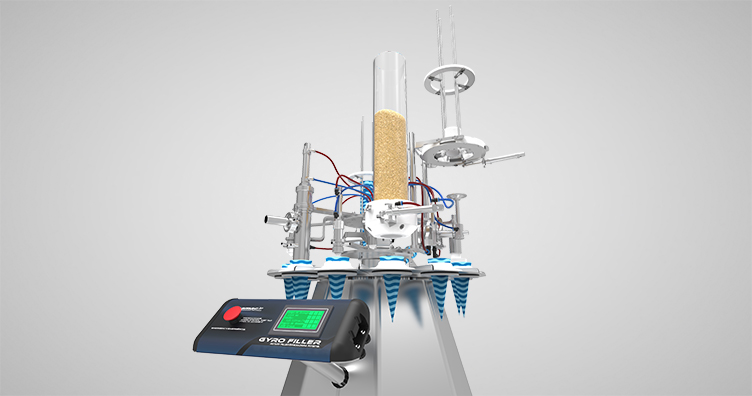

It can also be equipped with dispensers for chocolate, toppings, and granulates.

*This machine is not certified by ETL/UL/NSF rules.

*Please check the laws in your country about food preparation before finish your purchase.

Round Cups (up to 500 ml / 0.132 gal) Sundae

* Other volumes, models and measures by prior consultation.SINGLE FLAVOR CUPS

- Produces 600 to 4000 units/hour*;

- Packing volume of 90 ml a 500 ml / 0.024 a 0.132 gal;

- Ideal for packing liquids and pastes with application in the chemical, food, and cosmetics industries;

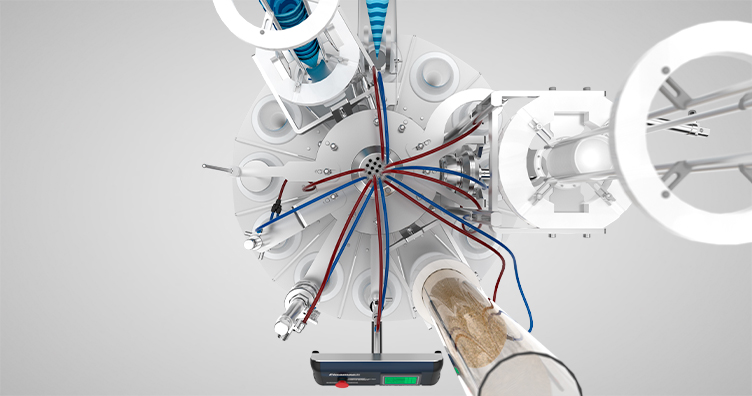

- Speed and packing volume are controlled electronically;

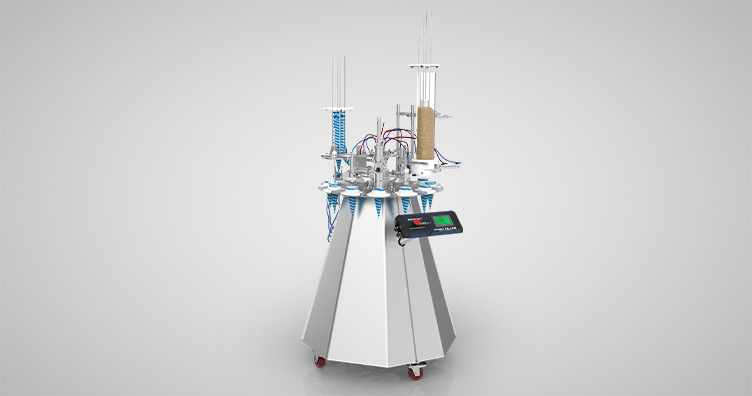

- 12 easy to configure stations;

- Up to 3 dispensing nozzles;

- Automatic and sequential stations disconnections;

- Self-adjusting production speed;

- Perfect synchronism, servodriven by microprocessor;

- Power source: 220/380V, tri-phase, 50/60 Hz;

- Optionals: volumetric dispenser, U.V. sterilizer, thermal-melting seal;

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

Business purpose

For medium size producers who need practical equipment that take up very little space. For those who need to obtain automatically-packed, industrial-quality ice cream with a controlled production cycle.

Sugestions

1 Gyrofiller + 1 Super C3

1 GyroFiller+ 1 Fruit Mix

1 Gyrofiller + from 1 to 3 Super C

1. Costs 50% less than the equivalent machines offered by other companies.

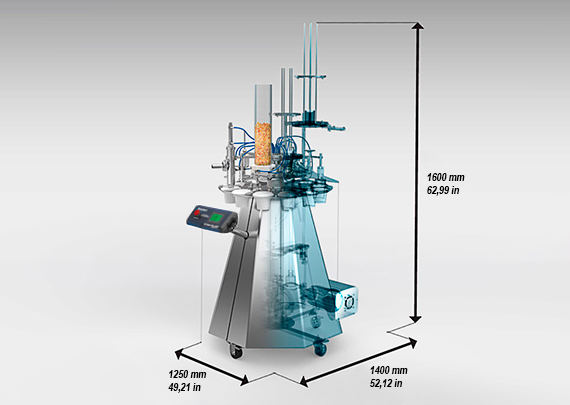

2. Occupies only 60% of the area of an equivalent machine.

3. Weighs 50% less than equivalent machines.

4. Maintenance costs are 30% lower because the machines have less parts.

5. Easy to wash and clean.

6. Easy to operate and safe. The automated start/finish operation avoids wasting ice cream and cups.

7. Easy to transport due to the reduced dimensions. This unique filling machine can also use rotary/lock wheels, since it operates smoothly.

8. An exclusive on board computer allows specific programs for each product to be filled, with precise adjustments during each stage of the process.

9. Uses compressed air to activate each stage of the operation, eliminating complex mechanisms that consistently cause problems.

10. The production speed allows the Gyrofiller to connect to both large and small machines. Equivalent machines are usually entirely mechanical (not digitally controlled) and do not offer a wide range of speeds.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.