This equipment will be available for sale in the 1st half of 2025

CHOOSE YOUR FLAVOR, YOUR COLOR AND YOUR ICE CREAM SHAPE ...

This machine will be certified for UL/NSF standards by 2023

Soft ice cream has become much better known around the world since the trend of McDonald's ice cream kiosks, Burger King and other fast food chains.

This is an ice cream produced on the spot in front of the customer and its great advantage is that it can be served in different places and not only in a closed ice cream shop or establishment.

Soft ice cream machines require no knowledge about ice cream formulations because in general mixtures are found premixed in the market. They can also produce frozen yogurt, milk shakes and ice slush.

They do not require specialized technicians to operate them, which facilitates the installation in any kind of commercial environment.

Many soft machines are installed on sidewalk streets in more centralized areas of the cities where there is a lot of foot traffic.

The equipment consists of two tanks, one for each flavor and these tanks keep the ice cream mixtures refrigerated. These mixtures are conducted towards two cylinders where they undergo beating, freezing and extracting with either two single flavors or one mixed flavor through valves controlled by levers placed on the front of the machine.

Most of the equipment for soft ice cream production have been using this same concept for decades. It is easy to distinguish them by their 3 levers lined up in front of the machine, the side levers serve single flavors and the middle lever serves a combination of the two.

Some improvements have been made in the automation of these operations but the functions have remained the same.

The competition between manufacturers of this type of machine was always based on tradition or "who had created the first machine". Only small constructive details have been added, with no significant improvement to the final product.

The machines have never lost that basic box style look and the construction standards have remained exactly the same for many years. A simple metal structure surrounded by stainless steel panels.

The new SHAPE line is the result of study and observation over many years and has arrived to break that dullness and same look of the current equipment used for soft ice cream production worldwide.

The name SHAPE stands for the variety of ice cream formats which can be produced with this new machine plus many new improvements that have never been seen in the market.

Soft ice cream will no longer be a simple swirl of two flavors. Get ready to amaze your customers with the new SHAPE Soft Serve Ice Cream Machine!

It is known that the air incorporated into the ice cream provides softness and it is responsible for what became worldwide known as SOFT ICE CREAM.

The amount of air incorporated into the ice cream ranges from 30% by volume, on machines having no pump for air injection, and up to 70% of its volume in machines having a pump.

The new SHAPE line is the only one in the world which incorporates air above 100%, an absolute novelty in the industry. This means that for each liter of mixture two liters of ice cream can be produced with quality and high profitability.

This high air rate is only reached by machines used in big ice cream industries such as Unilever and Nestlè. The SHAPE technology allows the same results in soft ice cream machine, on a smaller scale.

You may have noticed that soft ice cream comes out of the machine in a twisted star-shape, forming a conical design on the cup or cone where it is served.

The SHAPE allows the customer to choose different shapes during ice cream extraction, ranging from spaghetti fillets, star shape, square, sliced etc.

So imagine the variety of ways these shapes can make if the machine operator moves the cone or cup creatively as the ice cream comes out.

The SHAPE can be equipped with a pump of colored syrup fillets which follow the ice cream shapes. Yes, that's right, in addition to having the option of varying formats, you can also color the final product with four different syrups.

The SHAPE brings even greater news to be able to put these fillets on the mixed flavor. In conventional machines fillets can be added in only one flavor that the machine produces.

So, imagine a mixed vanilla and chocolate ice cream with green fillets of mint flavor. Still, you can put fillets in a vanilla ice cream, separate, or in a chocolate ice cream without touching the equipment. Only SHAPE can do this with a unique patented system.

Conventional machines require the installation of the colored fillets device in only one flavor, so if the client requests another flavor with colored fillets we cannot easily move this device to extract another flavor. That’s why the option of colored fillets is only offered with vanilla ice cream, and this device is definitely installed at the extraction of this flavor.

In conventional soft ice cream machines the product is beaten quickly because it must be served on the spot. This ends up making the ice cream a little sandy and without the required quantity of air to become soft.

The SHAPE has a multiple beating system, where the ice cream goes through several channels and is mixed with air, an absolute novelty in the world market.

In addition, the scraping of ice from the walls of SHAPE freezing cylinder is smoothly done by special blades designed to carefully cut through the ice and not overwhelm it, as done in conventional machines. Yet another great feature of the new SHAPE Soft Serve Machine.

The SHAPE machine is equipped with two independent tanks at its top that can prepare, heat and cool the mixture, ensuring its complete pasteurization.

Pasteurization eliminates harmful microorganisms and should be done every night, in the non-commercial period, for up to 15 days in a row, without the need to daily disassemble the machine components for cleaning. Conventional machines without pasteurization need to be disassembled every day for internal cleaning, requiring considerable labor. With the pasteurization system SHAPE eliminates this daily work and cleaning is done every 15 days, only. This represents a large differential in the operational cost of the equipment.

Inside the tanks there is an unprecedented flowing system that forces the mixture to pass through an apparatus that cools or heats it. In conventional machines the cooling and heating process is performed through the walls of the tanks but this causes the formation of ice on them, especially when they are not completely filled with mixture.

SHAPE machine cools or heats the mixture with an apparatus immersed in each tank so the serious problem of ice formation is completely eliminated.

The mixture is always kept under constant agitation, at the point of being produced, while avoiding the separation of the ingredients.

The tanks can be equipped with a water spray inside, facilitanting the cleaning process at the end of the period.

Drawn in a curved and inclined format, the SHAPE tanks cover is made of double tempered and heated glass to prevent the formation of moisture droplets.

In conventional machines the tanks lid is cold/flat and moisture formed on its walls just drip into the mixture, changing its composition throughout the day of use.

Furthermore, the new SHAPE lid acts as thermal insulation for very hot places or where it might be exposed to partial incidences of sunlight.

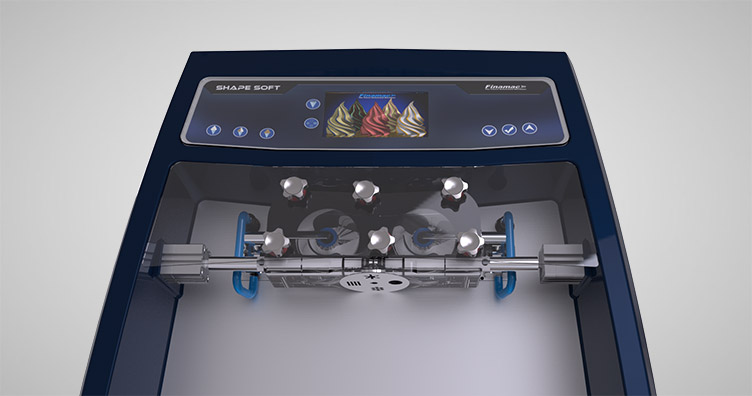

The first impact of the SHAPE line over conventional machines is caused by the absence of the three levers used for the ice cream extraction.

An absolute novelty in the market, you can now adjust the output flow of the ice cream and the desired time of extraction. This means that the operator, after setting two parameters, just presses a button and the machine doses the correct amount of ice cream in sufficient time to move the cone or cup for a good decoration.

This is done manually in conventional machines, pulling the lever with no precision and extracting the ice cream, but the amount is not always the same nor can you allow for the time needed for decoration of the product.

In SHAPE all the ice cream exits at the same amount and the operator can carefully repeat the decorating process.

In conventional machines you need to purchase additional equipment to accommodate cone and sundae cups to serve ice cream. Such devices serve as a dispenser of the recipients and must be accommodated near the equipment, usually hung on the side wall or on the machine itself, often becoming a nuisance.

The SHAPE comes with the possibility to integrate the dispenser in the machine without taking up any additional space, in addition to providing a much more beautiful and clean visual look.

Soft ice cream machines need to have their parts dismounted and sanitized at the end of the production period. In addition, these parts need to be stored in a dry and safe place and can only be reassembled in the machine just before starting production, to prevent the formation of mold and other hygienic drawbacks.

In conventional machines this storage is done outside the equipment, usually in separate cabinets, in most cases without the requirements of hygiene.

The SHAPE line comes equipped with a glass door in front of the equipment, which brings behind a cabinet 100% sanitary where these parts can be saved and attached separately, with safety and hygiene. The glass door also allows the placement of a sticker with the logo of your company or desired art, making the equipment much more attractive for your business.

In conventional machines is necessary to use a bucket or recipient on the front to wash the mixing tanks and the ice cream beating cylinders. In addition, the water from the tanks can only exit passing through the cylinders.

In SHAPE line the tanks can be washed separately from the cylinders and the water drainage is done directly at the back of the machine, with direct connection to the waste water network of your shop.

Likewise, the ice cream beater cylinders can be cleaned separately from the tanks where the mixture is prepared and water also flows to the back of the machine in direct connection to the waste water network of your shop.

Possible drops of ice cream or any excess in the extraction process can be automatically washed with a spray of water placed in ice cream outlet, with drainage also to the rear of the equipment.

Needless to say that the era of bucketsfor cleaning has ended with the arrival of SHAPE.

The SHAPE line represents the end of that basic box style look. This is the end of the concept that the machine needs to be hidden from the end user so that it does not appear, since its appearance is ugly, awkward or unhygienic.

The SHAPE machine alone is already a sales point !

It can be equipped with a motorized system to raise or lower the entire machine, allowing easy access to feed the tanks or to be adjusted to the best working height for the operator.

Its structure is based on innovative aeronautical technology with the casing made of high strength composite material,stainless steel surrounding it and other components in only one noise proof package without any amendments. Yes, the SHAPE line is provided with noise proof insulation!

With bold lines, its ergonomics allows full operator comfort making it easier to clean and maintain.

Just like Formula 1 cars, its resistance is superior to steel and it is very light. The customer also has the opportunity to select the color of his machine. It is the first soft serve machine in the world with this kind of integral construction.

Its panel is also made of tempered glass and customizable, with "soft touch" buttons, as in most modern mobile phones. It is the only machine that can be completely washed with a water jet.

Everything on this machine is smooth, clean and impressive looking. This is not just a "machine", it is a source of high quality ice cream, clear and fine in its appearance.

Water condensation equipment: requires a cooling tower.

Quality equipment for quality soft ice cream.

SHAPE is designed for manufacturing high quality ice cream and everything should start by the ingredients used.

You can buy ready mixes on the market in long-life packaging. If you want to make your own recipe, follow the steps below:

We need to define what a good quality food ingredient is. In the world market there exists the concept that ingredients for soft ice cream must come from this or that country, or from this or that company, and that only in this way it is possible to obtain positive results.

Bearing in mind that the technological development of soft ice cream and related equipment also may be governed by scientific knowledge, we will understand that good ingredients have some perfectly measurable technical characteristics, and that those ingredients can be obtained in several places, once we know what are the precise requirements.

Good quality milk necessary for the production of refined ice cream doesn’t need to come from a distant country only because it has a higher content of fat. The taste of milk, if it is a differential from a given location can be an advantage or a disadvantage because, in most cases, it is preferable that it is as neutral as possible.

Obviously some of these are characteristics of specific locations on the planet. However, the choice of flavors to be offered to customers can be worked so that the use of fruit arriving from afar is not necessary.

Frequently the job of processing fruit is naturally made by industries, resulting in condensed jams without losing their main characteristics. Manual processing of fruits sometimes does not result in quality compatible with industrial processes. This is because fruits are mainly composed of water and this water cannot be introduced directly into the ice cream. We need to extract the pulp of the fruit.

We call granules to the types of nuts, walnuts, peanuts, chocolates and even dried fruit, whose quality is not difficult to measure, because it depends heavily on the choice of the distributor, since the amounts are not large for a direct purchase from who produces these components. Ice cream training courses give some parameters so that these ingredients are within the standards of high quality.

Fats are responsible for softness and structure of ice cream, but are often treated as the bad part of the formula.

As in many of the foods we eat, fats are essential to the balance of the final product. Normally the richest ice cream has a higher fat content because it is significantly creamier and tastier.

Ice cream with low fat is classified in a different way, since it doesn't achieve the creaminess needed to be considered "premium" or superior quality ice cream.

Although eating fat hasn’t been recommended, it is still difficult to make a fat free chocolate. The same occurs with the ice cream.

Milk proteins are an important part of the ice cream but they’ve been often forgotten. It is said that ice cream is a refreshing delicacy only and therefore must not be nutritious.

Yes, ice cream is a nutritious food, and this is has been more than proven. Refined ice cream, with carefully balanced formulas, provide great pleasure and serves as an important food credit in healthy diets.

Some say that natural ice cream does not receive these types of ingredients. Or should not receive. It is a valid point of view.

However, the color and flavor are part of a well-designed product and, frequently, we are unable to reach a good color or flavor in a pineapple ice cream, for example, using only the fruit. As a rule it is white and not yellow, and with almost no pineapple flavor, especially if it is made with milk.

To extract the same pineapple color and flavor (which we taste from the fruit), many pineapples would be necessary to produce a small amount of ice cream. Even so, the result is not always equal to the fruit itself. To improve color and flavor there are natural colorants and flavorings without any contraindication, and fruit pulps, with almost all water removed.

The term stabilizer is commonly linked to industrialized food, which is not always correct. The most typical example of a stabilizer is an egg which is 100% natural.

We must separate what means thickener, emulsifier and preservative, all routinely reported as "stabilizers".

In the egg, the yolk is a natural emulsifier type, because it can stabilize the mixture of water and fat in ice cream and other foods. The egg white, in turn, has the power to retain particles of air in the mixture, then be very used to make "whipped cream".

Corn starch is able to absorb water and become more "gummy" or thicker, hence the concept of mixing thickener.

Salt is an example of natural preservative because it slows down the spoilage of food, inhibiting bacterial growth.

For each one of these components, there are various natural and synthetic options.

The total absence of these additives, even the natural ones, can be valid for the production of artisan ice creams, from the diet point of view, but may not be the best solution to a well-balanced ice cream, with physical characteristics which enable a proper and pleasant tasting of the product.

It would be like making a cake without yeast or whipped cream. And the cake will also need to last some time with the same characteristics. A cake that can be enjoyed only when it is hot, it is not exactly the desire of the most demanding consumers.

The same occurs with the ice cream without the fine touches of refinement. All ice cream recently made usually is good, even without any stabilizing, but needs to be savored at the moment, and with several restrictions. One of them, for example, is that it melts fast.

We are not recommending the use of artificial or natural additives out of the minimum and appropriate quantities. The quality needs a special touch. This touch is the use of these substances exactly as nature uses.

Often treated as the villains of ice cream, sugars are, in fact, the main actors of this product, which should be naturally sweet.

The biggest attraction is the ice cream unparalleled sense detected by our tong that link the sweetness and the cold. With no low temperature the sensation is not so good, as it isn’t with no sweet.

There are studies on the enhancement of sensations when you join temperature with sweetener or salt. Hence the soup is served hot and the ice cream is served cold.

Sugar also has the important function to lower the solidification temperature of ice cream mix which results in an creamy product without losing its softness.

There are types of sugar that increase or decrease the freezing point of the mixture and have different sweetness capacities. Courses of quality ice cream explain the differences between various types of sugars, including caloric and non-caloric.

Apart from high quality ingredients, it is necessary to promote a properly mixing of them before introducing the mixture into the soft ice cream freezer.

For that, the artisan ice cream maker usually uses conventional blenders or mixers provided with cutting blades, which rotate at high speed and promotes only the cutting of the particles that make up the ice cream mix.

The MIXER 15 and pasteurizers of Finamac are provided with an helix specifically designed to provide a perfect emulsion of fat and water contained in the ice cream, in addition of cutting and reducing size of the mixture ingredients. It is a special helix which rotates at lower speed and offers a result of homogenization of the mixture very close to that obtained with industrial high pressure homogenizers.

Pasteurization of the mixture raises its temperature up to 185 F and rapidly cool it down to 39 F destroying all harmful micro organisms that may exist.

SHAPE can pasteurize the mixture within its two own tanks, one of each flavor, or can work together with Finamac Pasteurizers PP 60 or PP 110, for bigger quantities.

A ready mix to produce ice cream, made with the mixer and pasteurization systems offered by Finamac, have very different characteristics that reflect a clear improvement in the quality of the final ice cream, providing greater incorporation of air during beating / freezing, much finer texture and greater absorption of flavor intensity.

Moreover, given the perfect mixture and emulsion, all the ingredients have higher chemical action, slowing the melting process and increasing the shelf life of the ice cream.

Just like baking a cake the ice cream beating process also has its peculiarities.

If making ice cream was so easy, it would be enough to use a cake mixer and take it to the home freezer. We know that this technique does not produce good quality ice cream.

The beating process should be done in the correct rotation with special blades scraping the ice cream from the internal part of the cylinder as it freezes against the wall. Moreover, cold is necessary in the correct amount and right time.

The way ice cream moves inside the cylinder is a technology that few companies know about and this is the moment when the air is incorporated into the product. Air in adequate amounts does not cost anything and gives softness and lightness to the quality the ice cream.

The ice cream beater/scraper in SHAPE is an innovative design that revolutionizes the current way of producing special ice cream. Conventional machines have only beaters and wide blades which shave and crudely blend the ice cream in a way similar to dough mixer for breads.

Refined ice cream is not exactly a bread dough or pizza, but a mixture which should result in a soft cream. SHAPE is equipped with scraper blades that do not "scrape" but "cut" thin the ice cream which is frozen at the freezing cylinder wall. The ice cream is blended and sliced by thin and independent blades, so that the ice is not thrown around but rather gently mixed.

The technology used in this process is the result of many years of observation and research. The difference in soft ice cream is remarkable.

The air in the soft ice cream makes up the great secret of the business. In addition to providing softness to the product, the air is responsible for the high profitability of this type of ice cream.

Conventional machines use air pumps that operate in conjunction with injection of the mixture in the freezer cylinder. This limits the amount of air in ice cream to 70% by volume. In practice, one can achieve an average 50% of air in ice cream, not more.

Machines that do not have air injection pump cannot inject more than 30% of air in the product, greatly reducing profitability.

Shape line is the first in the world that has an independent air injection, separated from the mixture injection, which gives incorporation of air in the ice cream over 100% of its volume.

Obviously it is necessary that the mixture is properly balanced to achieve this high level of aeration without losing quality of the final product.

The cylinders where the ice cream is beaten and frozen must be made with a thin wall for fast freezing. If it is not thin, the ice cream will be grainy with ice crystals formation.

Usually made of stainless steel, cylinders of soft serve machines are parts made from commercial tubes or stamped from sheet metal. Stainless steel is not a good thermal conductor which is why cooking pots made of this material have a copper bottom to help heat distribution in the food.

The cylinders of soft serve machines suffer the same difficulty. The cold standing around the cylinders has difficulty crossing the thick stainless steel that makes up the wall of the cylinders. The ice cream that is inside of these cylinders takes longer to get cold.

Formerly the cylinders used to freeze ice cream were made of copper, material more conductive than stainless steel, but copper is not suitable for direct contact with food.

To solve the problem of poor heat transfer of stainless steel the thickness of the cylinder wall was decreased so that there is less stainless steel for cold to pass through. The problem with this solution is that the wall can be very week.

SHAPE incorporates a forming technology which keeps the metallic structure of stainless steel very compact, with strength limits far superior from traditional stainless steel tubes or plates. This allows the use of a very thin wall without compromising its strength. The increase in heat transfer is impressive, substantially reducing the formation of ice crystals in ice cream and reducing your production time, in addition to substantial energy savings.

Also important to note that there are special categories of stainless steels with higher heat transfer capacity. SHAPE uses stainless steel with this advantage, and not common stainless steels used in conventional machines.

If you thought the thicker the wall of the cylinder the more robust the machine would be, well here's the first tip: the real technology of ice cream quality is within the thin wall of the cylinder and the thermo conductive characteristics of the material used.

How does the cold get to where the ice cream is beaten? Are you aware that a "bain-marie" makes the best quality sweets?

If the cooling gas directly touches the cylinder, your ice cream can be burnt, in the same way pudding is burnt when exposed to direct fire.

The cylinder must be involved with a distributed cooling system that enables its dosage and complete withdrawal at different times in the production of soft ice cream. This is an ultramodern technology that only Finamac has.

Contamination caused by ice cream machines that are not up to hygienic standards can be harmful.

No types of stainless steel in contact with foods, nor any type of plastic. There are special plastics and stainless steel used for each purpose.

Parts without rounded edges are difficult to wash and, furthermore, are dangerous. A well designed machine follows strict sanitary requirements.

When evaluating how SHAPE is disassembled, you can see that every aspect has been carefully designed to easily operate.

You'll notice some features that only SHAPE has:

- Firstly, observe the bottom of the cylinders of conventional machines; usually you will find a kind of metallic disk, without any rounded corner and an apparent crack (amendment) between this disk and the cylinder wall. This is the main point of contamination of soft serve machines. SHAPE cylinder are made with rounded corners and without any amendment, 100% within international health standards.

- The two tanks of ice cream mixture are provided with a water spray system to facilitate washing. The drainage of this water doesn’t pass through the cylinders, as in conventional machines, allowing separate washing.

- The cylinders can also be provided with internal water spray, which allows separate washing without washing the tanks simultaneously.

- At the cylinder bottom the scraper drive shaft is positioned inside the cylinder and not behind it, as in conventional machines, which cleaning is impossible. The shaft inside the cylinder enables 100% of hygiene.

- The scraper has detachable and easily washable knives, and is constructed so as to have no points of accumulation of product and impurities.

- The front lid of the cylinders is removable, safe and 100% hygienic, being hidden behind a panel to avoid improper handling.

- All corners are rounded and without any amendment that may accumulate impurities. The stainless steel finish is 100% sanitary. All gaskets are made of silicon non-toxic compound.

- The compartment where the cone or cup is placed for the extraction of ice cream is also 100% washable, avoiding accumulation of unwanted waste. A removable grid in this area makes it easy to keep it clean and flashy equipment.

Is the cost of your machine proportional to its weight?

150 kg gives you enough machine to produce ice cream. So, if your old machine weighs 500 kg / 1102.31 lb, the rest is excess.

Why would a manufacturer give you 350 kg / 771.62 lb of extra material?

The answer is simple: It is cheaper to produce a machine using cheaper materials, such as iron, even if it weighs much more than special plastics or thin stainless steel.

If lightness were a synonym for weakness, then airplanes would not be the safest type of transportation in the world.

When selecting Finamac equipment, you are getting the most modern machines, made with aeronautic technology. They are lighter and more durable than their heavy iron competitors.

What are the advantages?

Easy to move, for cleaning and changing locations.

Any vehicle can easily haul the SHAPE machine.

Easy to substitute parts.

For easy-handling you need safe equipment, and safety begins with a responsible design. Finamac is one of the few ice cream machine companies that follow international standards.

Our safety measures include electric, mechanical, and operational protection.

Operational failures occasionally occur. Finamac equipment is designed to be sufficiently intelligent in order to avoid damage and danger.

All moving parts installed inside the mixture tanks are also adequately protected against accidental handling.

Electric sensors for the equipment disconnection in case of overload. Thermal sensors also detect ice cream beater overload due accidental ice formation or presence of solids that may block its rotation.

There is no electric charge in front of the machine, nor in the control panel, which operates by soft touch on a thick glass with sensors behind the glass and without any contact with them.

With a digital display that shows all operations that are being executed, and with interlocking sequential operations, there is no way the operator committing faults without being warned or even blocked by the electronic controller.

How much does it cost to maintain your equipment?

Many times we only pay attention to the initial cost of the machine, and forget to ask about replacement parts, technical assistance services, etc.

That’s what frequently happens with a lot of products, especially among computer accessories such as ink jet printers, where the replacement parts exceed the price of the product.

If your equipment is designed with modular and recyclable components, easy to substitute, you will be free of unexpected maintenance costs. If it had been designed with a non-modular parts with no knowledge about their life cycle, you would be subjected to specialized services and hidden prices. Hermetic and modular components receive the factory warranty and are free from manual intervention.

All components used in Finamac equipment, including the structural parts, are modular and hermetic, allowing for easy replacement and modernization. You will not be stuck with an old machine, difficult to resale. It is not made with heavy iron, as in conventional equipment, that is inflexible and not compatible with emerging technology.

The crate for SHAPE is modular, demountable and reusable. Yes, because your machine can change places, can be sent for maintenance and may one day be sold in perfect condition, properly protected by its original packaging.

We use the most modern technology available, assuring low maintenance costs and high resale value.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

For entrepreneurs from different areas who have locations where there is a lot of foot traffic and where the ice cream can be sold on the spot.

Bakeries, ice cream parlors, bars, restaurants, snack bars, pharmacies, bookstores and various stores can easily put this machine in front of the space or shop with simple training to operate and make sales that are even larger than the total sales of the store.

For its innovative design and its refined technical characteristics the high quality ice cream produced by Shape and the way it is presented meet even the most demanding consumers.

2 ou 3 Shape + PP60 + Mixer 15: for stores with various flavors of soft ice cream.

1 Shape + 1 Robopop: for aerated ice pops production.

1 Shape + PP110 + Gyrofiller: for industrial production of sundaes and cones.

1. The soft ice cream represents 20% of the global market of ice cream and in some countries its share is even higher. Hence, the huge amount of outlets of this kind of ice cream, in addition to McDonald's, Burger King and others.

2. There is no other type of commercial activity with such a high profit margin because the soft ice cream has no storage cost and its composition contains large percentage of air, especially if the machine is equipped with air injection pump.

3. There is no waste or melted ice cream like that of ice cream stored inside freezers, since the machine only produces what is consumed, and the production is instantaneous, made directly in front of customers. Before being produced the cooled mixture is kept in the machine and can be used throughout the day.

4. Being beaten and frozen "on the spot", the ice cream has unrivaled softness never done by ice cream that is stored in freezers. Hence, the name "SOFT ice cream", or creamy ice cream.

5. You do not need to be knowledgeable of the ice cream business and how to make it as the mixture can be found premixed on the market and the equipment operation is very simple, unlike machines for the production of industrial ice cream, which require skilled people for its operation and technical knowledge about formulations.

6. The mixture of ice cream can also be prepared very easily and requires no special equipment, just an ordinary blender or Finamac MIXER 15 (more robust). The ingredients can be easily found on the market.

7. The electrical installation can be single phase, which greatly facilitates the placement of equipment in different places, or three phase.

8. Because it is compact and has wheels it makes it easier to move and transport, as this type of equipment can be used in several places.

9. In addition to the famous ice cream cones this machine also produces sundaes, small cups, milk shakes and other types of ice cream including ice slush!

10. This is the first and only soft serve machine design which is 100% original, holding several patents and many improvements since 1995. No equipment from anywhere in the world has the technological advances that this equipment has.

11. First equipment in the world to use frequency inverter drives in the ice cream beater engine which saves energy and wearing down of parts.

12. First equipment in the world to work with a compressor relief start valve, which enables large number of starts and the use of single-phase compressors.

13. First equipment in the world to use a multi-part ice cream beater, which facilitates cleaning and sanitizing of equipment ease when replacing of worn parts.

14. First equipment in the world to use integral construction making the machine much lighter and stronger.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.